A Beginner’s Guide to Water Wells

For homeowners seeking a dependable and cost-effective source of fresh water, selecting the appropriate water well type is of utmost importance. With options such as drilled, driven, and dug wells, each choice comes with its own advantages and limitations. Drilled wells offer greater depth, longer lifespan, and specialized equipment, while driven wells are more affordable but have a shorter lifespan and lower water yield. Dug wells, on the other hand, are simple and low-cost but demand regular testing and maintenance to ensure water quality. In this article, we will explore the key factors to consider when choosing a water well type, including water quality, cost, maintenance, location, legal requirements, pump selection, and pipe materials. By understanding these considerations and seeking professional guidance, homeowners can make well-informed decisions to secure a reliable and safe water supply for their homes.

Pros and Cons of Drilled Wells

Drilled wells are one of the most common types of water wells found in residential areas. These wells are created by drilling a hole into the ground using a specialized drilling rig. One of the biggest advantages of drilled wells is their depth, which allows them to tap into deeper aquifers and access a larger supply of water. Additionally, drilled wells tend to have a longer lifespan compared to other types of wells. However, there are some downsides to consider. The installation cost of a drilled well can be higher due to the specialized equipment and expertise required. Furthermore, the maintenance and repairs of drilled wells can also be more costly. It is important to regularly test the water quality of a drilled well to ensure it remains safe for consumption.

Drilled wells offer a reliable and consistent water supply, making them a popular choice for homeowners. However, it is important to consider the initial investment and ongoing maintenance costs associated with this type of well. Additionally, if the groundwater in your area is prone to contamination, extra precautions and filtration systems may be necessary.

Pros and Cons of Driven Wells

Driven wells, also known as sand-point wells or shallow wells, are another option to consider. These wells are created by driving a pipe into the ground until it reaches the water table. One of the main advantages of driven wells is their affordability. They are typically less expensive to install compared to drilled wells. Additionally, driven wells can be a good option for areas with shallow water tables. However, there are some drawbacks to consider. Driven wells tend to have a shorter lifespan compared to drilled wells, and they may not be suitable for areas with deep water tables. The water yield of driven wells can also be lower, which may limit their usage, especially during periods of high water demand.

Driven wells can be a cost-effective solution for homeowners who are looking for a basic water supply. However, it is important to consider the limitations of this type of well, such as the depth of the water table and the overall lifespan of the well. Additionally, regular maintenance and testing should be conducted to ensure the water quality remains satisfactory.

Pros and Cons of Dug Wells

Dug wells, also known as hand-dug wells or traditional wells, have been used for centuries as a source of water. These wells are manually dug into the ground until they reach the water table. One of the main advantages of dug wells is their simplicity and low cost. They can be constructed with basic tools and materials, making them an accessible option for homeowners on a budget. Additionally, dug wells can be easily maintained and repaired. However, there are some disadvantages to consider. Dug wells are more susceptible to contamination compared to other types of wells. They are also limited in terms of water yield and may not be suitable for areas with high water demand.

Dug wells can be a viable option for homeowners who have limited resources and are looking for a basic water supply. However, it is important to be aware of the potential risks associated with this type of well, such as contamination and limited water yield. Regular testing and maintenance are essential to ensure the water quality remains safe.

Factors to Consider When Choosing a Water Well Type

When choosing a water well type for your home, there are several factors to consider. Firstly, you need to assess the water quality of the area. Different well types can vary in terms of their ability to provide clean and safe drinking water. Additionally, you should consider the water yield of the well. This refers to the amount of water the well can provide, which is particularly important if you have a large household or rely heavily on water for irrigation purposes. Another important factor to consider is the installation cost. Drilled wells tend to have higher upfront costs compared to driven or dug wells. Lastly, you should also think about the maintenance and upkeep of the well. Some well types require more frequent maintenance and repairs, which can add to the overall cost.

Assessing the Water Quality of Different Well Types

The water quality of different well types can vary depending on various factors such as geological conditions and the presence of contaminants in the area. It is important to regularly test the water quality of your well to ensure it remains safe for consumption. Drilled wells, for example, tend to have better water quality compared to dug wells due to their deeper reach and natural filtration through layers of rock and soil. However, it is still crucial to conduct regular testing and take appropriate measures to address any issues that may arise.

Determining the Water Yield of Different Well Types

The water yield of a well refers to the amount of water it can provide. This is an important consideration, especially if you have a large household or rely heavily on water for irrigation purposes. Drilled wells generally have a higher water yield compared to driven or dug wells due to their deeper reach and larger diameter. However, the water yield can also be influenced by factors such as the geology of the area and the overall water table level. It is important to consult with a professional to determine the water yield of different well types in your specific location.

Cost Comparison of Different Well Types

The cost of installing a water well can vary depending on the type of well and the specific requirements of your property. Drilled wells tend to have higher installation costs compared to driven or dug wells due to the specialized equipment and expertise required. However, it is important to consider the long-term costs as well. Drilled wells generally have a longer lifespan compared to driven or dug wells, which means they may require less frequent repairs and maintenance. Additionally, the water yield of a well can also impact its overall cost-effectiveness. It is important to weigh the upfront costs against the long-term benefits and consider your budget and specific needs when choosing a water well type.

Maintenance and Upkeep of Different Well Types

Regular maintenance and upkeep are essential to ensure the optimal performance and longevity of your water well. The maintenance requirements can vary depending on the type of well you have. Drilled wells, for example, may require periodic inspections, pump maintenance, and water quality testing. Dug wells, on the other hand, may require more frequent cleaning and disinfection to prevent contamination. It is important to be aware of the specific maintenance requirements of your well and schedule regular inspections and servicing to address any issues before they escalate.

Conclusion and Recommendation

Choosing the right water well type for your home is an important decision that requires careful consideration of various factors. Each well type has its own set of advantages and disadvantages, ranging from installation costs and water quality to maintenance requirements and environmental impact. Drilled wells offer a reliable and consistent water supply, but they come with higher upfront costs and potential maintenance expenses. Driven wells are more affordable but may have limitations in terms of water yield and lifespan. Dug wells are simple and low cost, but they are more susceptible to contamination and may not provide sufficient water for high-demand situations. Ultimately, the best choice for your home will depend on your specific needs, budget, and location. It is recommended to consult with a professional well contractor who can assess your property and provide expert advice tailored to your situation. By considering all the pros and cons, you can make an informed decision and ensure a consistent supply of clean and fresh water for your home.

By following the outlined pros and cons of different water well types, assessing various factors such as installation costs, maintenance requirements, water quality, and environmental impact, homeowners can make an informed decision on which water well type is best suited for their needs. Whether it be a drilled well, driven well, or dug well, each option has its own benefits and drawbacks. It is crucial to consider the specific requirements of your property, as well as your budget and long-term goals. By choosing the right water well type, homeowners can enjoy a reliable and sustainable supply of fresh water for years to come.

Factors to Consider When Choosing a Location for a Water Well

Selecting the right location for a water well is crucial to ensure its efficiency and longevity. Several factors should be taken into account when determining the ideal spot. First and foremost, it’s important to assess the proximity to potential water sources. Understanding local hydrology and geology is essential to identify areas where underground water is likely to be found. Conducting a hydrogeological study can help determine the depth, quality, and yield of the water in a particular area.

Accessibility is another critical factor to consider. The location of the well should be easily accessible for drilling equipment and future maintenance purposes. Additionally, it’s important to be mindful of potential sources of contamination, such as septic systems or chemical storage areas. Keeping a safe distance from these sources is crucial to ensure the quality of the water.

Lastly, legal, and regulatory requirements must be taken into account. Different jurisdictions may have specific regulations regarding the installation and operation of water wells. It’s important to familiarize yourself with these regulations to ensure compliance and avoid any legal issues down the line.

The Best Locations for Water Wells in Rural Areas

Rural areas often offer plentiful opportunities for water well installations. The absence of dense urban development allows for more flexibility in choosing the ideal location. In rural areas, the best locations for water wells are often determined by the underlying geology and hydrology of the region.

One of the most promising locations for water wells in rural areas is near rivers or streams. These water bodies provide a natural indication of underground water sources and can be a reliable location for drilling a well. Additionally, areas with high water tables, such as low-lying regions, are often excellent choices for water well installations. The shallow depth of the water table in these areas makes drilling easier and more cost-effective.

Another consideration in rural areas is the presence of natural springs or ponds. These natural water sources indicate the presence of underground aquifers and can be an excellent starting point for drilling a water well. By tapping into these existing water sources, you can ensure a more consistent and sustainable water supply.

The Best Locations for Water Wells in Urban Areas

Finding suitable locations for water wells in urban areas can be more challenging due to the dense development and limited available space. However, there are still hidden gems to be discovered even in bustling cities. In urban areas, the best locations for water wells often require creative thinking and careful consideration of available options.

One option is to explore the possibility of drilling a well in a backyard or open space within a property. While space may be limited, some urban properties have enough room to accommodate a water well. This option provides homeowners with a reliable water source while minimizing the need to rely solely on the municipal supply.

Another option is to consider community wells or shared water sources in urban areas. In some cases, neighborhoods or communities may come together to create shared water wells that serve multiple households. This approach not only provides a cost-effective solution but also fosters a sense of community and sustainability.

Geological Considerations for Water Well Locations

Understanding the geological composition of an area is vital when selecting the best location for a water well. Different types of rocks and soil formations have varying permeability and water-holding capacities, directly affecting the well’s yield and overall performance.

Sedimentary rocks, such as sandstone and limestone, often provide excellent water-bearing formations. These rocks have interconnected spaces, or aquifers, that can store and transmit water. Drilling a well in areas with sedimentary rocks can result in higher water yields and better water quality.

On the other hand, areas with igneous or metamorphic rocks, such as granite or gneiss, may pose more significant challenges for water well installations. These rocks are typically less permeable and have fewer interconnected spaces for water storage. However, fractures and faults within these rocks can create pathways for underground water flow, making them potential locations for water wells.

Legal and Regulatory Requirements for Water Well Installations

Before embarking on a water well installation, it’s important to understand the legal and regulatory requirements in your jurisdiction. Different regions have specific rules and guidelines for drilling and operating water wells to ensure the protection of groundwater resources and public health.

One common requirement is the need for permits or licenses for water well installations. These permits often involve submitting detailed plans and specifications to the relevant authorities for review and approval. Additionally, some regions may require periodic water quality testing and well inspections to ensure compliance with health and safety standards.

It’s also crucial to be aware of any setback requirements that dictate the minimum distance between a well and potential source of contamination, such as septic systems or underground storage tanks. Adhering to these setback requirements is essential to protect the water supply from potential contamination.

Tips for Maintaining and Troubleshooting Water Wells

Once a water well is installed, proper maintenance is crucial to ensure its longevity and efficiency. Regular inspections and maintenance activities can help identify potential issues early on and prevent costly repairs or replacements. Here are some tips to keep your water well in optimal condition:

- Regularly test the water quality to ensure it meets safety standards. This includes testing for bacteria, nitrates, and other contaminants.

- Inspect the well casing and seals for any signs of damage or deterioration. Addressing these issues promptly can prevent the infiltration of contaminants.

- Keep the well area clear of debris and potential sources of contamination, such as chemicals or fertilizers.

- Monitor the water level in the well to ensure it remains at an adequate level. A significant drop in water level may indicate a problem with the well or surrounding aquifer.

- Familiarize yourself with the operation and maintenance manual provided by the well drilling company. Follow the recommended maintenance schedule and procedures.

In case of any issues or concerns with your water well, it’s best to consult a professional well contractor who can assess the problem and provide the necessary solutions. Attempting to troubleshoot or repair complex well issues without the proper knowledge and experience can lead to further damage and costly repairs.

The Benefits of Hiring a Professional for Water Well Drilling and Installation

When it comes to water well drilling and installation, hiring a professional is paramount. Professionals have the expertise, experience, and specialized equipment necessary to locate the best spots for water wells and ensure a successful installation. Here are some benefits of hiring a professional for your water well needs:

- Expertise: Professionals have in-depth knowledge of hydrogeology, geology, and local regulations. They can assess the geological conditions and hydrological characteristics of an area to determine the most suitable location for a water well.

- Efficiency: Professionals use state-of-the-art equipment and techniques to drill wells efficiently and effectively. This ensures that the well is installed correctly and yields optimal results.

- Compliance: Professionals are well-versed in the legal and regulatory requirements for water well installations. They can guide you through the permitting process and ensure compliance with all relevant regulations.

- Safety: Water well drilling involves various safety risks, such as the potential for cave-ins or contact with hazardous materials. Professionals follow strict safety protocols to minimize these risks and protect both the workers and the environment.

- Long-Term Support: Professional well contractors offer ongoing support and maintenance services to keep your well in optimal condition. They can provide routine inspections, water quality testing, and troubleshooting services as needed.

By entrusting your water well drilling and installation to professionals, you can have peace of mind knowing that your water source is reliable, safe, and compliant with all regulations.

Common Challenges and Solutions in Finding Suitable Locations for Water Wells

Finding suitable locations for water wells can present several challenges, regardless of whether you’re in a rural or urban area. Understanding these challenges and their potential solutions can help streamline the process and increase the chances of success.

One common challenge is identifying the most promising areas for drilling. Geology and hydrology studies can help pinpoint potential water sources, but they are not foolproof. In some cases, drilling test wells or conducting geophysical surveys may be necessary to gather additional data and confirm the presence of water.

Accessibility can also be a challenge, especially in remote or densely populated areas. Limited road access or restrictions on drilling equipment can make it difficult to reach potential well locations. In such cases, exploring alternative drilling techniques, such as directional drilling, may be necessary to access water sources.

Another challenge is the presence of contaminants or poor water quality. Some areas may have high levels of naturally occurring contaminants, such as arsenic or iron, which can pose health risks. Water treatment solutions, such as filtration or chemical treatments, may be required to ensure the water meets safety standards.

In urban areas, space constraints can be a significant obstacle. Limited available land and underground utilities can make it challenging to find suitable locations for water wells. In such cases, exploring alternative options, such as shared community wells or rooftop rainwater harvesting systems, can provide viable solutions.

Choosing the Perfect Pump for Your Water Well: A Comprehensive Guide

Looking to find the perfect pump for your water well? Choosing the right pump is crucial to ensure a reliable and efficient water supply for your household or business. With so many options available in the market, it can be overwhelming to narrow down your choices. From understanding pump ratings to maintenance tips, this section has got you covered. So, let’s dive in and find the perfect pump that will keep your water flowing smoothly for years to come!

Types of Water Well Pumps

When it comes to water well pumps, there are several types to choose from, each with its own advantages and suitability for different well setups. The three most common types of water well pumps are submersible pumps, jet pumps, and centrifugal pumps.

Submersible pumps are designed to be submerged in the well and are typically placed deep below the water level. They are highly efficient, quiet, and have a longer lifespan compared to other pump types. Submersible pumps are suitable for wells with a larger diameter and are commonly used in deep wells.

Jet pumps are installed above ground and use suction to draw water from the well. They are available in two types: shallow well jet pumps and deep well jet pumps. Shallow well jet pumps are used for wells with a depth of up to 25 feet, while deep well jet pumps can handle depths up to 120 feet. Jet pumps are relatively easy to install and maintain, making them a popular choice for shallower wells.

Centrifugal pumps are non-submersible pumps that use centrifugal force to move water. They are typically used in situations where the water source is not deep and the demand for water is low to moderate. Centrifugal pumps are easy to install and require minimal maintenance, making them a cost-effective option for many homeowners.

Factors to Consider When Choosing a Water Well Pump

Selecting the right water well pump involves considering several factors to ensure optimal performance and longevity. Let’s explore these factors in detail.

Evaluating Your Water Usage Needs

Before choosing a water well pump, it’s essential to evaluate your water usage needs. Consider the number of occupants in your household or employees in your business, as well as the typical water usage patterns. Calculate the average daily water demand, including activities such as showering, washing dishes, laundry, and irrigation. Understanding your water usage needs will help determine the pump’s flow rate requirements, ensuring an adequate supply of water.

Understanding Pump Specifications and Terminology

To make an informed decision, it’s crucial to understand the various specifications and terminology associated with water well pumps. Here are some key terms to familiarize yourself with:

- Flow rate: The amount of water a pump can deliver in gallons per minute (GPM) or liters per minute (LPM).

- Total dynamic head (TDH): The total height or pressure that the pump must overcome to deliver water to the desired location.

- Horsepower (HP): The power rating of the pump, indicating its ability to move water against resistance.

- Voltage: The electrical power supply required to operate the pump effectively.

- Pump efficiency: The ratio of the output power (water flow) to the input power (electricity consumed).

Understanding these specifications will help you determine the appropriate pump size and type for your specific needs.

Common Features and Accessories of Water Well Pumps

When choosing a water well pump, it’s important to consider the features and accessories that come with it. Some common features to look for include:

- Automatic shut-off: A feature that automatically shuts off the pump when the water reaches a certain level, preventing damage from dry running.

- Pressure switches: These switches control the pump’s operation based on the water pressure in the system, ensuring consistent water supply.

- Pressure tanks: These tanks store pressurized water, reducing the need for the pump to cycle on and off frequently.

Accessories such as pressure gauges, check valves, and control boxes may also be necessary depending on your specific setup. It’s important to discuss these options with a knowledgeable professional to ensure compatibility with your water well system.

Assessing the Depth and Yield of Your Well

The depth and yield of your well play a significant role in determining the type and size of pump you need. Here’s how to assess these factors:

Determining the Appropriate Horsepower for Your Pump

The horsepower (HP) rating of a water well pump is crucial in ensuring it can meet the water demand of your household or business. The appropriate horsepower depends on factors such as the well depth, water flow requirements, and the total dynamic head (TDH) of the system. A pump with insufficient horsepower may struggle to deliver water, while one with excessive horsepower may consume more energy than necessary. Consult with a professional to accurately determine the appropriate horsepower for your specific well setup.

Comparing Different Pump Brands and Models

Once you have a clear understanding of your water usage needs and the technical requirements of your well, it’s time to compare different pump brands and models. Consider factors such as reliability, reputation, customer reviews, and warranty coverage. Look for pumps that are energy-efficient, durable, and backed by a reputable manufacturer. Consulting with a professional or seeking recommendations from trusted sources can help narrow down your options and make an informed decision.

Maintenance and Troubleshooting Tips for Water Well Pumps

To ensure the longevity and efficient operation of your water well pump, regular maintenance is essential. Here are some basic maintenance and troubleshooting tips:

- Monitor water pressure: Regularly check the water pressure to ensure it remains within the recommended range. Low pressure may indicate a problem with the pump or the well system.

- Inspect the pump and motor: Periodically inspect the pump and motor for any signs of damage, leaks, or unusual noises. Address any issues promptly to prevent further damage and ensure optimal performance.

- Clean the pump intake: If your pump has a suction intake, regularly clean it to prevent clogging and maintain smooth water flow.

- Test the pump performance: Occasionally test the pump’s performance by measuring the flow rate and pressure. This will help identify any decline in performance and allow for timely repairs or adjustments.

Remember, regular maintenance and timely repairs can save you from costly breakdowns and ensure a reliable water supply.

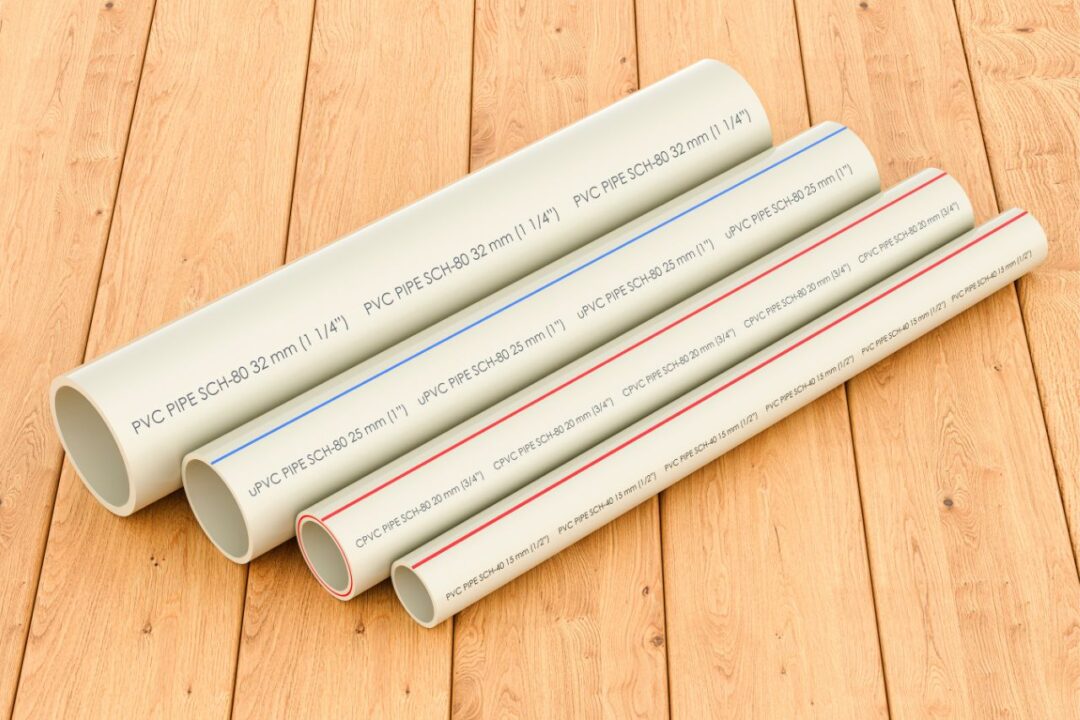

Choosing the right pipes for your water well

Finding the right pipes is crucial for ensuring the longevity, efficiency, and safety of your water well. Get ready to dive into the world of pipe materials and discover the key factors to consider when choosing the right pipes for your water well construction!

Importance of choosing the right materials for water well construction

When it comes to constructing a water well, choosing the right materials is of utmost importance. The quality and durability of the pipes used can directly impact the longevity, efficiency, and safety of your well. By selecting the appropriate pipe material, you can ensure that your water well operates smoothly and provides clean and safe water for years to come.

Factors to consider when choosing materials for water well construction

Before delving into the different pipe materials available, it’s crucial to consider a few key factors that can influence your decision. These factors include:

- Water quality: The quality of the water in your area plays a significant role in determining the suitability of certain pipe materials. For instance, if you have acidic or corrosive water, you’ll need pipes that can withstand such conditions.

- Budget: Your budget will also play a role in your pipe material selection. Some materials may be more expensive upfront but offer greater longevity, while others may be more affordable but require more frequent maintenance.

- Environmental conditions: Consider the environmental conditions surrounding your water well. Factors like soil composition, temperature fluctuations, and exposure to sunlight can impact the performance of different pipe materials.

- Installation method: The method of installation you choose can also influence the type of pipe material that is most suitable. Some materials may be easier to work with in certain installation scenarios.

By carefully considering these factors, you can make an informed decision and select the pipe material that best meets your specific needs.

Common materials used in water well construction

Now that you understand the importance of choosing the right pipe material and the factors to consider, let’s explore the common materials used in water well construction:

- PVC (Polyvinyl Chloride):

PVC pipes are a popular choice for water well construction due to their affordability and ease of installation. They are lightweight, durable, and resistant to corrosion, making them suitable for a wide range of water well applications. However, PVC pipes may not be suitable for areas with highly corrosive water or extreme temperature fluctuations.

- Galvanized steel:

Galvanized steel pipes are known for their strength and durability. They are resistant to rust and can withstand high pressure, making them a suitable choice for deep water wells. However, galvanized steel pipes can be more expensive than other materials, and their installation requires specialized tools and skills.

- Polyethylene:

Polyethylene pipes are gaining popularity in water well construction due to their flexibility, chemical resistance, and affordability. They are easy to install and can adapt to various soil conditions. However, polyethylene pipes may not be suitable for areas with high temperatures or exposure to sunlight, as they can degrade over time.

- Stainless steel:

Stainless steel pipes offer excellent corrosion resistance and durability. They are ideal for water wells with highly corrosive water or extreme environmental conditions. While stainless steel pipes are more expensive, they have a long lifespan and require minimal maintenance.

Pros and cons of different materials for water well construction

Each pipe material comes with its own set of advantages and disadvantages. Let’s take a closer look at the pros and cons of the different materials discussed:

- PVC:

Pros:

- Affordable

- Lightweight and easy to handle

- Resistant to corrosion

- Versatile and suitable for various applications

Cons:

- Not suitable for highly corrosive water

- May not withstand extreme temperature fluctuations

- Galvanized steel:

Pros:

- Strong and durable

- Resistant to rust

- Suitable for deep water wells and high-pressure applications

Cons:

- More expensive than other materials

- Requires specialized tools and skills for installation

- Polyethylene:

Pros:

- Flexible and easy to install

- Chemical resistant

- Affordable

Cons:

- Not suitable for high temperatures or exposure to sunlight

- May degrade over time

- Stainless steel:

Pros:

- Excellent corrosion resistance

- Durable and long-lasting

- Low maintenance

Cons:

- More expensive than other materials

Best materials for different types of water wells

The best pipe material for your water well will depend on the specific type of well you are constructing. Here are some recommendations based on different well types:

- Shallow wells: For shallow wells, PVC pipes are often the preferred choice due to their affordability, ease of installation, and resistance to corrosion.

- Deep wells: Galvanized steel pipes are commonly used for deep wells as they offer the necessary strength and durability to withstand high pressure.

- Wells with corrosive water: In areas with highly corrosive water, stainless steel pipes are the best option. They provide excellent corrosion resistance and ensure the longevity of the water well.

- Wells in extreme environmental conditions: If your water well is exposed to extreme temperatures or other harsh environmental conditions, stainless steel pipes are the most suitable choice due to their durability and resistance.

Tips for selecting materials for water well construction

To ensure you make the right choice when selecting pipe materials for water well construction, consider the following tips:

- Consult with professionals: Seek advice from experienced well drillers or consult with professionals in the industry. They can provide valuable insights and recommendations based on your specific needs and the local conditions.

- Conduct thorough research: Take the time to research different pipe materials, their properties, and their suitability for your water well project. Consider factors like durability, corrosion resistance, installation requirements, and maintenance needs.

- Consider long-term costs: While upfront costs are important, it’s essential to consider the long-term costs associated with different pipe materials. Materials that require less maintenance and have a longer lifespan may prove to be more cost-effective in the long run.

- Evaluate local regulations: Familiarize yourself with local regulations and requirements for water well construction. Some areas may have specific guidelines regarding the use of certain pipe materials.

By following these tips, you can make an informed decision and select the pipe material that best meets your requirements.

Costs and availability of different materials for water well construction

The costs and availability of pipe materials can vary depending on various factors such as location, demand, and market conditions. Here is a general overview of the costs and availability of the different materials discussed:

- PVC: PVC pipes are widely available and are generally more affordable compared to other materials. Their popularity and ease of production contribute to their accessibility.

- Galvanized steel: Galvanized steel pipes tend to be more expensive than PVC pipes due to the additional manufacturing processes involved. Availability may vary depending on the region and demand.

- Polyethylene: Polyethylene pipes are commonly available and are generally affordable. However, availability may be limited in certain regions or specialized applications.

- Stainless steel: Stainless steel pipes are typically more expensive than other materials due to the higher cost of the raw materials and manufacturing processes. Availability may vary depending on the region and demand.

It is advisable to check with local suppliers and compare prices to ensure you get the best value for your money.

Maintenance and longevity of different materials for water well construction

The maintenance requirements and longevity of pipe materials can significantly impact the overall cost and performance of your water well. Here’s a closer look at the maintenance and longevity of the different materials discussed:

- PVC: PVC pipes require minimal maintenance and have a relatively long lifespan. Regular inspections to check for leaks or damage are recommended.

- Galvanized steel: Galvanized steel pipes are durable and have a long lifespan. However, periodic maintenance is essential to prevent rust and corrosion.

- Polyethylene: Polyethylene pipes are generally low maintenance and have a long lifespan. UV protection and proper installation are crucial to ensure their longevity.

- Stainless steel: Stainless steel pipes are known for their durability and require minimal maintenance. They have an exceptionally long lifespan, making them a cost-effective choice in the long run.

By understanding the maintenance requirements and lifespan of different pipe materials, you can plan for routine inspections and maintenance to extend the life of your water well.

Hiring a professional for water well construction

While some homeowners may choose to embark on a DIY water well construction project, it is highly recommended to hire a professional well driller. Well drillers have the necessary expertise, equipment, and experience to ensure the successful construction and operation of your water well.

When selecting a professional, consider the following:

- Licensing and certifications: Ensure that the well driller is licensed and certified in your area. This ensures that they meet the necessary standards for water well construction.

- Experience and reputation: Look for well drillers with a proven track record of successful projects and positive customer reviews. A reputable well driller will have the expertise to guide you in selecting the right pipe materials.

- Insurance and warranties: Verify that the well driller has adequate insurance coverage and offers warranties for their work. This provides peace of mind and protection in case of any unforeseen issues.

By hiring a professional, you can rely on their expertise to guide you through the entire water well construction process and ensure that the appropriate pipe materials are used.

Conclusion

In conclusion, selecting the right water well type is crucial for homeowners seeking a reliable and cost-effective source of fresh water. Each well type, whether it’s drilled, driven, or dug, comes with its own advantages and limitations. Drilled wells offer depth, longer lifespan, and specialized equipment, while driven wells are less expensive but have a shorter lifespan and lower water yield. Dug wells are simple and low-cost but require regular testing and maintenance to ensure water quality.

When choosing a water well type, factors such as water quality, cost, and maintenance should be considered. Drilled wells generally have a higher water yield but require higher upfront costs. Regular maintenance is essential for all well types to ensure optimal performance and longevity.

The location of the water well should also be carefully considered, taking into account proximity to water sources, accessibility, and potential sources of contamination. Geological considerations play a significant role, with different rock formations affecting the well’s yield and performance.

Legal and regulatory requirements for water well installations should be adhered to, including permits, water quality testing, and setback requirements to prevent contamination. Hiring a professional well contractor is recommended for their expertise in hydrogeology, local regulations, and equipment.

Choosing the right water well pump involves evaluating water usage needs, understanding pump specifications, and considering features and accessories. Regular maintenance and troubleshooting are essential for pump performance.

Selecting the appropriate pipe material for water well construction is crucial, considering factors such as water quality, budget, and environmental conditions. PVC, galvanized steel, polyethylene, and stainless steel are common materials with their own pros and cons.

By consulting professionals, conducting thorough research, and considering long-term costs, homeowners can make informed decisions about water well construction, ensuring a reliable and safe water supply for their homes. Hiring a reputable well driller provides peace of mind and expertise throughout the entire process.