What Does a Well Foot Valve Do?

Have you ever wondered how well systems maintain their efficiency and longevity? The answer lies in a crucial component known as the foot valve. Installed at the intake of the suction line, this valve plays a vital role in preventing damage to the pump and keeping it primed.

A well foot valve operates similarly to a check valve, allowing water to flow in one direction while preventing backflow into the well. This functionality is essential for wells, especially those deeper than 4 meters, to maintain the pump’s prime and prevent potential damage.

Key Takeaways

- The primary function of a foot valve is to prevent backflow into the well.

- It helps in keeping the pump primed, thus enhancing its efficiency.

- Foot valves are crucial for wells deeper than 4 meters.

- Different types of foot valves are available, including ball, flapper, membrane, and spring types.

- A strainer on the inlet port prevents debris from entering the valve.

Understanding Well Foot Valves

In the context of well systems, understanding the role of a foot valve is essential for optimal performance. A well foot valve is a critical component that ensures the efficient operation of a well system.

Definition and Basic Function

A well foot valve is a type of valve that is installed at the bottom of a well or borehole. Its primary function is to prevent backflow into the well, thereby maintaining the prime of the pump and ensuring a consistent flow of water. As noted by industry experts, “The foot valve is a crucial element in preventing the loss of prime and reducing the strain on the pump.”

“The foot valve is a crucial element in preventing the loss of prime and reducing the strain on the pump.”

The basic function of a foot valve is to allow water to flow into the pump while preventing it from flowing back into the well. This is achieved through a simple yet effective mechanism that opens to allow inflow and closes to prevent backflow.

Where Foot Valves Are Located in Well Systems

Foot valves are typically located at the bottom of a well or borehole, submerged in water. The exact positioning can vary depending on the type of well.

Shallow Wells vs. Deep Wells

In shallow wells, the foot valve is usually positioned closer to the surface, whereas in deep wells, it is located deeper, often requiring more robust construction to withstand higher pressures. The depth and type of well influence the design and placement of the foot valve.

Optimal Positioning for Maximum Efficiency

The optimal positioning of a foot valve is crucial for maximizing efficiency. It should be placed in a way that minimizes sediment intake and reduces the risk of clogging. Proper positioning ensures that the valve operates effectively, contributing to the overall efficiency of the well system.

What Does a Well Foot Valve Do?

A well foot valve is a crucial component in well systems, playing a vital role in ensuring the efficient operation of water pumps. It is designed to serve specific purposes that are essential for the smooth functioning of the water supply system.

Primary Functions and Purpose

The primary function of a well foot valve is to prevent water from flowing backward in the well system. This is crucial because backflow can cause the pump to lose its prime, leading to inefficiency and potential damage. The well foot valve benefits include reducing the strain on the pump and ensuring a consistent water supply.

By allowing water to flow in only one direction, the foot valve maintains the pressure in the system, thereby enhancing the overall efficiency of the water pump.

The Role in Water Pump Systems

In water pump systems, the foot valve plays a pivotal role. It is typically located at the bottom of the well or suction pipe, submerged in water. The foot valve’s role is two-fold:

Preventing Water Backflow

By preventing water from flowing back into the well, the foot valve ensures that the pump does not have to work harder than necessary. This prevents unnecessary strain on the pump, thereby prolonging its lifespan.

Maintaining Prime in the Pump

The foot valve helps in maintaining the prime in the pump by ensuring that the water column remains intact. This is crucial for the pump’s efficiency and effectiveness, as losing prime can lead to reduced water flow and increased energy consumption.

Here’s a summary of the key features and benefits of well foot valves in a tabular format:

| Feature | Benefit |

|---|---|

| Prevents backflow | Maintains pump prime |

| Reduces strain on the pump | Prolongs pump lifespan |

| Ensures consistent water supply | Enhances system efficiency |

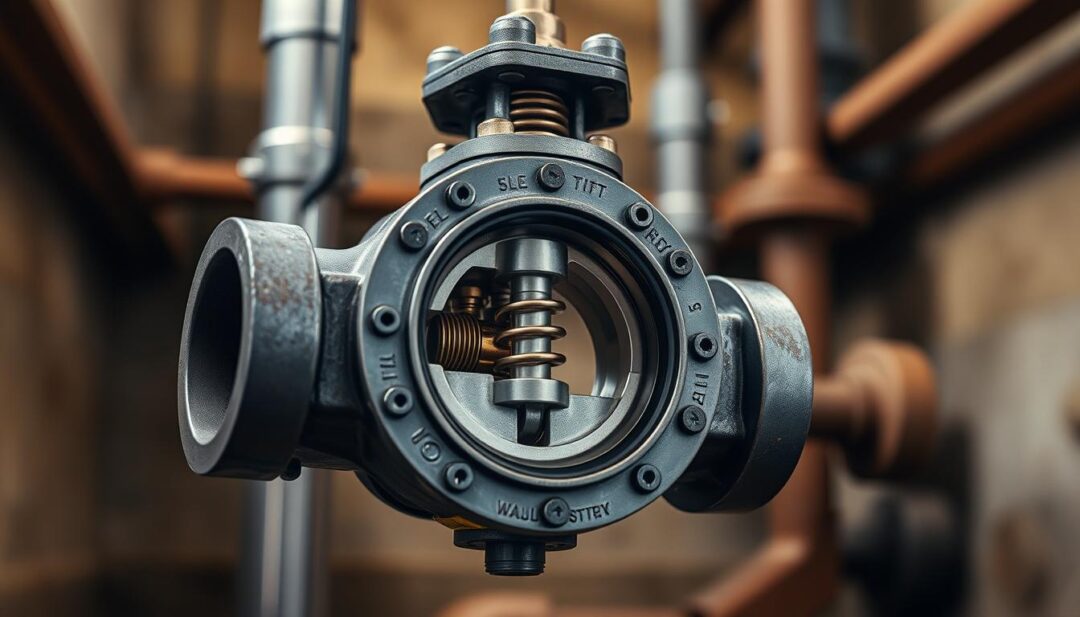

Components of a Well Foot Valve

The effectiveness of a well foot valve depends on its internal components. A well foot valve is a critical part of a well system, and understanding its components is essential for maintaining the system’s efficiency.

Key Parts and Materials

The construction of a well foot valve involves several key parts, each made from materials that can withstand the conditions of the well environment.

Body Construction

The body of a foot valve is typically made from durable materials such as brass, stainless steel, or PVC. The choice of material depends on the well’s operating conditions and the type of water being pumped.

Sealing Mechanisms

Sealing mechanisms are crucial for preventing backflow. These are often made from rubber or other flexible materials that can create a tight seal.

Screens and Strainers

Screens and strainers are used to filter out debris and sediment from the water entering the valve, protecting the pump from damage.

How Components Work Together

The components of a well foot valve work together to ensure the valve operates correctly. When the pump is activated, the valve opens, allowing water to flow into the pump. When the pump is turned off, the valve closes, preventing water from flowing back out. This one-way flow is crucial for maintaining the prime of the pump and ensuring efficient operation.

For more information on foot valves and their applications, visit Kamat’s Foot Valves page.

| Component | Material | Function |

|---|---|---|

| Body | Brass, Stainless Steel, PVC | Structural integrity |

| Sealing Mechanism | Rubber, Flexible Materials | Prevent backflow |

| Screens and Strainers | Metal or Plastic Mesh | Filter debris |

Types of Well Foot Valves

Understanding the different types of well foot valves is crucial for selecting the right one for your well system. Well foot valves are categorized based on their design, functionality, and the specific requirements they are meant to fulfill.

Poppet Foot Valves

Poppet foot valves are known for their simple design and effectiveness. They use a poppet valve that moves up and down to control the flow of water. This type is often used in smaller well systems due to its compact size and reliability.

Flapper Foot Valves

Flapper foot valves utilize a hinged flap that opens to allow water to pass through and closes to prevent backflow. They are praised for their durability and are suitable for a variety of well system configurations.

Spring-Loaded Foot Valves

Spring-loaded foot valves incorporate a spring mechanism that assists in the closure of the valve, enhancing its sealing capabilities. This design is beneficial in systems where pressure variations are significant.

Comparing Different Valve Types

When comparing the different types of well foot valves, several factors come into play, including durability, maintenance needs, and cost. The table below summarizes some key differences:

| Valve Type | Durability | Maintenance Needs | Cost |

|---|---|---|---|

| Poppet | High | Low | Moderate |

| Flapper | Very High | Moderate | Higher |

| Spring-Loaded | High | Low | Higher |

As highlighted by industry experts, “The choice of foot valve can significantly impact the efficiency and longevity of a well system.” Selecting the appropriate type based on the specific needs of your well is essential for optimal performance.

“The right foot valve can make all the difference in the performance and lifespan of your well system.”

In conclusion, understanding the various types of well foot valves and their characteristics is vital for making an informed decision. By considering factors such as durability, maintenance, and cost, you can choose the most suitable valve for your well system.

Working Principle of Well Foot Valves

The well foot valve operates on a straightforward yet effective principle that ensures the smooth operation of water pump systems. This principle is centered around the valve’s ability to control the flow of water, ensuring that it moves in one direction, thereby preventing backflow and maintaining the prime of the pump.

The One-Way Flow Mechanism

The core functionality of a well foot valve lies in its one-way flow mechanism. This mechanism allows water to enter the pump during the suction phase while preventing it from flowing back into the well during the holding phase. The one-way flow is typically achieved through a valve that opens under suction pressure and closes when the pressure reverses.

Pressure Dynamics in Operation

The operation of a well foot valve is deeply influenced by pressure dynamics. The valve’s functionality can be broken down into two critical phases: suction and holding.

Suction Phase

During the suction phase, the pump creates a negative pressure that opens the foot valve, allowing water to flow into the pump. This phase is crucial for initiating the water flow into the pumping system.

Holding Phase

In the holding phase, the pressure inside the pump increases, causing the foot valve to close. This closure prevents the water from flowing back into the well, maintaining the prime of the pump and ensuring continuous operation.

The harmonious operation of these phases, governed by the pressure dynamics, ensures that the well foot valve effectively regulates the water flow, enhancing the overall efficiency and reliability of the well system.

Benefits and Advantages of Well Foot Valves

The incorporation of well foot valves in water pumping systems offers numerous benefits, enhancing the overall efficiency and reliability of the system.

Preventing Pump Priming Issues

One of the primary advantages of well foot valves is their ability to prevent pump priming issues. By maintaining water within the pump and suction line, these valves ensure that the pump remains primed and ready for operation, thus reducing downtime and increasing overall system reliability.

Extending Pump Life

Well foot valves contribute to extending the life of the pump by preventing dry running and reducing the strain caused by frequent start-ups. This protective function helps in minimizing wear and tear on the pump, thereby prolonging its operational lifespan.

Improving System Efficiency

The use of well foot valves improves system efficiency by ensuring a consistent flow of water and preventing backflow. This one-way flow mechanism is crucial for maintaining the integrity of the water supply and ensuring that the system operates as intended.

Cost Savings Over Time

By reducing the need for frequent repairs, minimizing downtime, and extending the life of the pump, well foot valves lead to significant cost savings over time. The initial investment in a high-quality foot valve can result in substantial long-term savings, making it a cost-effective solution for well system operators.

Selecting the Right Foot Valve for Your Well

The selection of an appropriate foot valve is a critical decision that affects the overall efficiency of your well system. A well foot valve plays a crucial role in the functioning of your well, and choosing the correct one is essential for optimal performance and longevity.

Factors to Consider When Choosing

When selecting a foot valve for your well, several factors need to be considered to ensure you make the right choice. These factors include the depth and diameter of your well, the quality of the water, and the required flow rate.

Well Depth and Diameter

The depth and diameter of your well are critical in determining the type of foot valve you need. Deeper wells require foot valves that can withstand higher pressures, while the diameter of the well will dictate the size of the valve. It’s essential to choose a valve that fits snugly inside the well casing to prevent unnecessary friction and wear.

Water Quality Considerations

The quality of the water in your well also plays a significant role in selecting a foot valve. Water with high levels of sediment or corrosive elements requires a valve made from durable, resistant materials. This ensures the longevity of the valve and prevents frequent replacements.

Flow Rate Requirements

The flow rate required by your well system is another crucial factor. The foot valve must be able to handle the necessary flow rate without causing undue resistance or pressure drop. Selecting a valve that matches your system’s flow rate requirements is vital for efficient operation.

Material Considerations for Different Environments

The environment in which the foot valve will operate is a significant consideration. Different materials offer various benefits and drawbacks, making some more suitable for certain conditions than others.

Brass and Bronze Valves

Brass and bronze valves are known for their durability and resistance to corrosion. They are often used in wells with high water quality and moderate pressures. These materials offer a good balance between cost and performance.

PVC and Plastic Options

PVC and other plastic materials are lightweight and resistant to corrosion, making them ideal for wells with aggressive water chemistry. They are also generally more affordable than metal options, providing a cost-effective solution.

Stainless Steel Varieties

Stainless steel foot valves offer exceptional durability and resistance to corrosion, making them suitable for wells with harsh water conditions or high pressures. Although they are typically more expensive, their longevity can justify the higher upfront cost.

Installing a Well Foot Valve

The installation of a well foot valve is a crucial step in ensuring the efficiency and longevity of your well system. A well-installed foot valve can significantly enhance the performance of your well pump, reducing the risk of priming issues and prolonging the lifespan of the pump.

Pre-Installation Considerations

Before installing a well foot valve, it’s essential to consider several factors. These include the type of well system you have, the depth of your well, and the specifications of the foot valve you are installing. Understanding these factors will help you choose the right foot valve and ensure a successful installation.

Additionally, inspect the foot valve for any damage or defects before installation. Check for any blockages or debris that could interfere with the valve’s operation.

Step-by-Step Installation Process

Installing a well foot valve involves several key steps:

- Measure the depth of your well to determine the correct placement of the foot valve.

- Attach the foot valve to the end of the suction pipe, ensuring it is securely connected.

- Lower the suction pipe into the well, taking care not to damage the valve or pipe.

- Once the pipe is in place, check the system for any leaks or issues.

Common Installation Mistakes to Avoid

Even with careful planning, mistakes can occur during the installation process. Two common issues to watch out for are improper depth placement and inadequate sealing.

Improper Depth Placement

Placing the foot valve at an incorrect depth can lead to reduced system efficiency and increased risk of pump damage. Ensure you measure the well depth accurately and position the valve accordingly.

Inadequate Sealing

Failing to properly seal connections can result in leaks and system failures. Use appropriate sealing materials and techniques to ensure all connections are secure.

The importance of a well foot valve cannot be overstated, as it provides numerous benefits, including preventing pump priming issues, extending pump life, and improving system efficiency. By following the proper installation procedures, you can maximize these benefits and ensure your well system operates effectively.

| Installation Aspect | Importance | Common Issues |

|---|---|---|

| Depth Placement | High | Improper depth can lead to reduced efficiency and pump damage. |

| Sealing | High | Inadequate sealing can cause leaks and system failures. |

| Valve Inspection | Medium | Failing to inspect the valve can lead to undetected damage or defects. |

Troubleshooting Well Foot Valve Issues

Effective troubleshooting of well foot valves is essential for preventing system downtime and ensuring the longevity of your water pumping system. Well foot valves play a critical role in the operation of well systems, and when they fail, it can lead to a range of problems.

Signs of a Failing Foot Valve

Identifying the signs of a failing foot valve is the first step in troubleshooting. Common indicators include:

- Reduced water pressure

- Increased energy consumption

- Frequent pump cycling

- Water hammer or banging noises

- Visible signs of leakage or damage

Recognizing these signs early can help prevent more severe issues from developing.

Common Problems and Their Causes

Well foot valves can fail due to a variety of reasons. Some common problems include:

- Wear and tear on valve components

- Corrosion due to exposure to certain chemicals or minerals

- Improper installation or sizing

- Debris or sediment clogging the valve

Understanding the root cause of the problem is crucial for effective troubleshooting and repair.

Diagnostic Steps

To diagnose issues with a well foot valve, follow these steps:

- Inspect the valve for visible signs of damage or wear.

- Check the system’s pressure gauges for irregular readings.

- Listen for unusual noises during pump operation.

- Test the valve’s functionality by isolating it from the rest of the system.

Repair vs. Replacement Decisions

When deciding whether to repair or replace a faulty well foot valve, consider the extent of the damage, the age of the valve, and the cost of replacement parts. In many cases, replacing the valve entirely may be the most cost-effective solution in the long run.

Conclusion

Understanding the role of well foot valves is crucial for maintaining efficient water supply systems. As discussed, these valves play a vital part in preventing pump priming issues, extending pump life, and improving overall system efficiency.

The well foot valve working principle is based on a one-way flow mechanism that allows water to flow into the pump while preventing backflow. This mechanism is essential for maintaining the prime of the pump and ensuring a consistent water supply.

The advantages of well foot valves, including cost savings over time and improved system reliability, make them a valuable component in well systems. By selecting the right foot valve for your specific needs and following proper installation and maintenance procedures, you can maximize the efficiency and lifespan of your well system.

By grasping the importance of well foot valves and their benefits, you can ensure a reliable and efficient water supply system that meets your needs. The well foot valve advantages are clear, and incorporating these valves into your well system can have a significant impact on its overall performance.