Well Casing 101: Everything You Need to Know

Have you ever wondered what protects your well water from contamination? The answer lies in the well casing, a crucial component of any well system.

A well casing is essentially a pipe that lines the well, preventing dirt and debris from mixing with the water. But what exactly is a well casing, and how does it work? For a detailed explanation, you can explore the concept further on this page, which provides an in-depth look into well casings, including their types, such as PVC and steel, and the differences between well seals and well caps.

In this article, we’ll delve into the world of well casings, exploring their importance, types, and functions. By the end of this article, you’ll have a comprehensive understanding of well casings and their role in maintaining safe and clean drinking water.

Key Takeaways

- Understanding the definition and importance of well casings.

- Exploring the different types of well casings, including PVC and steel.

- Learning about the primary function of well casings in preventing contamination.

- Discovering the differences between well seals and well caps.

- Understanding how to measure well casings for proper fitting.

What’s a Well Casing: Definition and Basic Function

Well casings are tubular structures that line the drilled wellbore, playing a vital role in its operation and longevity. They are a fundamental component in the construction of wells, serving multiple critical functions that ensure the well’s stability and efficiency.

The Structural Component of Wells

A well casing acts as the structural backbone of a well, providing the necessary support to maintain its integrity. This is crucial for the well’s operation, as it prevents the wellbore from caving in and ensures that the well remains functional over its intended lifespan.

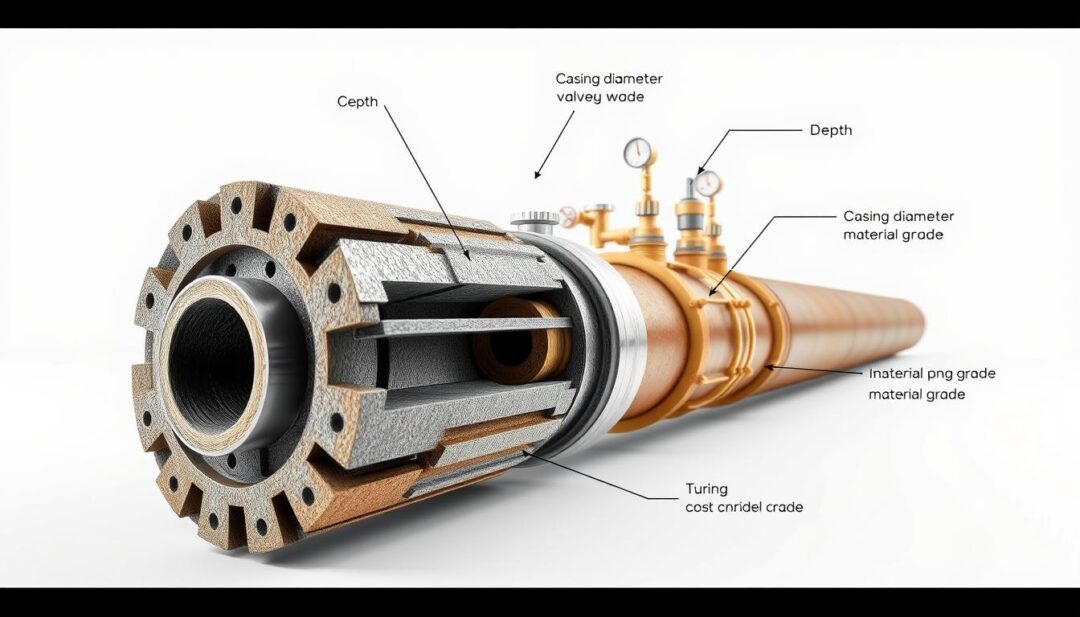

Physical Characteristics and Components

The physical characteristics of a well casing include its diameter, material composition, and wall thickness. These characteristics are determined based on the specific requirements of the well, including the type of resource being extracted and the geological conditions of the well site.

How Well Casings Support the Well Structure

Well casings support the well structure by providing a durable lining that withstands the surrounding geological pressures and prevents collapse. This lining also facilitates the extraction of resources by maintaining a clear pathway from the surface to the resource reservoir.

Primary Purposes of Well Casings

The primary purposes of well casings are multifaceted, focusing on ensuring the well’s operational integrity and safety. These purposes include preventing collapse and contamination, as well as facilitating the extraction of resources.

Preventing Collapse and Contamination

One of the critical functions of a well casing is to prevent the collapse of the wellbore. By providing a strong, durable lining, it ensures that the well remains open and functional. Additionally, well casings prevent contamination by isolating the wellbore from surrounding geological formations that could potentially compromise the quality of the extracted resource.

Facilitating Water or Resource Extraction

Well casings also play a crucial role in facilitating the extraction of water or other resources. By maintaining a clear and stable pathway, they enable the efficient operation of the well, ensuring that resources can be extracted safely and effectively.

The Importance of Well Casings in Different Industries

The significance of well casings cannot be overstated, as they are vital in multiple sectors, from water supply to oil and gas extraction. Well casings are fundamental to the safe and efficient operation of wells across various industries.

Role in Water Well Systems

Well casings play a critical role in water well systems, ensuring the quality and safety of the water supply. They prevent contamination by isolating the well from surrounding soil and groundwater.

Residential Water Supply Protection

In residential areas, well casings protect drinking water by preventing surface contaminants from entering the well. Properly installed casings are crucial for maintaining water quality.

Agricultural Applications

For agricultural purposes, well casings are essential for irrigation systems, safeguarding water used for crops and livestock. This helps in maintaining the health and productivity of agricultural operations.

Critical Functions in Oil and Gas Wells

In the oil and gas industry, well casings are indispensable for maintaining the integrity of the well. They provide structural support and prevent the leakage of hydrocarbons into surrounding formations.

Pressure Management

Well casings help manage pressure within oil and gas wells, preventing blowouts and ensuring safe operating conditions.

Zonal Isolation

They also facilitate zonal isolation, separating different geological formations and preventing the migration of fluids between zones.

Environmental Protection Aspects

Well casings contribute significantly to environmental protection by safeguarding groundwater resources and preventing cross-contamination.

Groundwater Protection Mechanisms

By encasing the well, these casings prevent surface pollutants from reaching the groundwater, thus protecting aquifers.

Preventing Cross-Contamination

Well casings also prevent the cross-contamination of different water-bearing formations, maintaining the quality of groundwater.

Types of Well Casing and Their Applications

The diverse range of well casing types reflects the complexity and variability of drilling operations in different environments. Well casings are not a uniform product; they come in various types, each designed to address specific challenges and requirements in well construction.

Conductor Casing

Conductor casing is the outermost casing that is used to stabilize the top portion of the well and prevent collapse during drilling. It is typically the largest diameter casing used in a well.

Surface Casing

Surface casing is used to isolate the well from the surrounding environment and to protect freshwater aquifers. It is usually set at a depth that ensures the stability of the well and prevents contamination.

Intermediate Casing

Intermediate casing is used to isolate different zones within the well and to provide additional structural support. It is often used in complex wells with multiple drilling stages.

Production Casing

Production casing is the innermost casing that is used to produce oil or gas from the well. It is designed to withstand the pressures and corrosive environments associated with hydrocarbon production.

Liner Casing

Liner casing is a type of casing that is not run from the surface but is hung from the previous casing string. It is used to reduce costs and improve drilling efficiency.

The selection of the appropriate type of well casing depends on various factors, including the geology of the area, the depth of the well, and the intended use of the well.

| Type of Casing | Primary Function | Typical Depth |

|---|---|---|

| Conductor Casing | Stabilize top portion of well | Surface to 100 ft |

| Surface Casing | Isolate well from environment | 100 to 1,000 ft |

| Intermediate Casing | Isolate different zones | 1,000 to 5,000 ft |

| Production Casing | Produce oil or gas | Often to the total depth |

| Liner Casing | Reduce costs and improve efficiency | Varies, often deeper sections |

As highlighted by industry experts, “The right choice of well casing can significantly impact the safety, efficiency, and environmental sustainability of drilling operations.” Effective well casing design and selection are critical to the success of any drilling project.

Well Casing Materials: Choosing the Right Option

Selecting the appropriate well casing material is crucial for the longevity and safety of a well. The material chosen must withstand the environmental conditions and operational demands of the well.

Steel Casings and Their Varieties

Steel casings are widely used due to their strength and durability. They are suitable for various well applications, including water and oil wells.

Carbon Steel Options

Carbon steel is a popular choice for well casings due to its high strength and cost-effectiveness. It is often used in water wells and other applications where corrosion is not a significant concern.

Stainless Steel Applications

Stainless steel casings offer excellent corrosion resistance, making them ideal for wells in corrosive environments. They are more expensive than carbon steel but provide long-term benefits.

PVC and Other Plastic Options

PVC and other plastic materials are also used for well casings, offering advantages such as corrosion resistance and lower costs compared to steel. For more information on protecting your well, visit Discover the Best Well Water Cover Ideas for Your.

PVC Strength Classifications

PVC casings come in different strength classifications, allowing for flexibility in design and application. They are commonly used in water wells.

Fiberglass and Composite Materials

Fiberglass and composite materials offer a combination of strength, corrosion resistance, and durability. They are used in challenging environments where other materials may fail.

Specialty Materials for Challenging Environments

In environments with extreme conditions, such as high temperatures or corrosive substances, specialty materials are used. These materials provide the necessary resistance to ensure the well’s integrity.

Corrosion-Resistant Alloys

Corrosion-resistant alloys are used in wells where the fluid or gas being extracted is corrosive. These alloys provide long-term protection against corrosion.

High-Temperature Applications

For wells operating at high temperatures, materials with high thermal resistance are selected. These materials maintain their integrity under extreme heat.

Well Casing Design Considerations

The design of a well casing plays a pivotal role in determining the efficiency and safety of well operations. A well-designed casing ensures the structural integrity of the well, prevents collapse, and facilitates the extraction process.

Determining the Appropriate Well Casing Depth

Setting the correct depth for a well casing is crucial and depends on several factors.

Geological Factors

Geological formations and their characteristics significantly influence the depth at which a well casing should be set. Different formations have varying levels of stability and resistance to collapse.

Regulatory Requirements in the US

In the United States, regulatory bodies such as the Environmental Protection Agency (EPA) and state-specific agencies provide guidelines on the minimum depth requirements for well casings based on environmental and safety considerations.

Diameter Selection Factors

The diameter of a well casing is another critical design parameter that affects the well’s performance.

Flow Rate Requirements

The casing diameter must be sufficient to accommodate the required flow rate of the well, ensuring that it can meet the demand for water or other resources.

Pump Size Compatibility

Additionally, the casing diameter must be compatible with the size of the pump to be installed, allowing for efficient operation and easy maintenance.

Strength and Pressure Requirements

The well casing must also be designed to withstand various stresses and pressures.

Collapse Resistance

One key consideration is the casing’s resistance to collapse under external pressure, which can be caused by the surrounding geological formations.

Tensile Strength Needs

Another important factor is the tensile strength required to support the weight of the casing and any additional loads it may bear during installation and operation.

Well Casing Installation Process

The well casing installation process is a complex operation that involves several key steps, from initial planning to the final sealing of the casing in place.

Pre-Installation Planning

Before the actual installation begins, thorough pre-installation planning is crucial. This phase ensures that the installation is carried out efficiently and effectively.

Site Assessment

A comprehensive site assessment is conducted to evaluate the geological conditions and potential environmental impacts. This assessment helps in determining the appropriate depth and diameter of the well casing.

Regulatory Compliance in the United States

Ensuring regulatory compliance is vital. In the United States, this involves adhering to Environmental Protection Agency (EPA) guidelines and other relevant state regulations. Compliance is crucial for avoiding legal issues and ensuring the well’s safety and longevity.

Installation Techniques and Equipment

The actual installation of the well casing involves specialized techniques and equipment. Drilling methods are selected based on the geological formation and the type of well being constructed.

Drilling Methods

Different drilling methods, such as rotary drilling or percussion drilling, are employed depending on the site conditions. The choice of method affects the efficiency and cost of the installation process.

Casing Insertion Procedures

Once the well is drilled, the casing is carefully inserted into the wellbore. This process requires precise alignment and handling to prevent damage to the casing and the wellbore.

Cementing and Sealing Procedures

Cementing is a critical step in the well casing installation process, providing a seal between the casing and the wellbore. This prevents fluid migration and ensures the well’s integrity.

Primary Cementing Techniques

Primary cementing involves pumping cement slurry down the casing and up the annulus. This creates a strong bond between the casing and the formation, sealing the well effectively.

Testing for Proper Seals

After cementing, the well is tested to verify the integrity of the seal. This involves pressure testing and other diagnostic techniques to ensure that the well casing is properly sealed and functioning as intended.

Maintenance and Well Casing Repair

The longevity and efficiency of well casings depend significantly on proper maintenance and timely repairs. Regular upkeep not only extends the lifespan of the well but also ensures its optimal performance.

Common Well Casing Problems

Well casings are susceptible to various issues, including corrosion, damage from external forces, and material degradation over time. Identifying these problems early is crucial for effective maintenance.

Identifying Damage Signs

Signs of damage include visible corrosion, leaks, and structural deformities. Regular inspections can help detect these issues before they become major problems.

Diagnostic Methods

Diagnostic techniques such as CCTV inspections and acoustic logging can be employed to assess the condition of well casings. These methods provide valuable insights into the integrity of the casing.

Well Casing Corrosion: Causes and Prevention

Corrosion is a significant threat to well casings, particularly in environments with high chemical activity. Understanding the causes and implementing preventive measures is essential.

Chemical Factors in Corrosion

Chemical factors, including exposure to corrosive substances and electrochemical reactions, play a significant role in the corrosion process. For more detailed guidelines on managing such challenges, refer to resources like practical guidelines for cementing new casing inside existing.

Protective Measures and Treatments

Applying protective coatings and using cathodic protection are effective methods for preventing corrosion. Regular maintenance and monitoring can also mitigate corrosion risks.

Repair Methods and Technologies

Various techniques are available for repairing damaged well casings, ranging from patching and relining to more complex interventions.

Patching and Relining Options

Patching involves repairing specific sections of the casing, while relining entails installing a new liner inside the existing casing. Both methods have their applications depending on the extent of the damage.

When to Replace vs. Repair

Deciding whether to repair or replace a well casing depends on the severity of the damage and the casing’s overall condition. A thorough assessment is necessary to make an informed decision.

| Repair Method | Description | Applicability |

|---|---|---|

| Patching | Repairing specific damaged sections | Localized damage |

| Relining | Installing a new liner inside the existing casing | Extensive damage or corrosion |

| Replacement | Replacing the entire well casing | Severe damage or end of lifespan |

Well Casing Cost Factors and Considerations

A comprehensive analysis of well casing costs is essential for optimizing drilling operations and reducing expenses. The financial aspects of well casing involve several key factors that need to be carefully considered.

Material Cost Comparisons

The choice of material for well casing significantly impacts the overall cost. Different materials offer varying levels of durability and resistance to corrosion.

Initial Investment Analysis

The initial cost of well casing materials can vary substantially. For instance, steel casings are often more expensive upfront compared to PVC or other plastic options. However, their durability and strength may justify the higher initial investment.

Longevity and Value Considerations

While initial costs are important, it’s equally crucial to consider the longevity and value that different materials offer over time. High-quality materials may reduce long-term maintenance and replacement costs.

Installation Expenses

In addition to material costs, installation expenses play a significant role in the total cost of well casing.

Labor and Equipment Costs

Labor costs for installing well casing can vary based on the complexity of the project and the expertise required. Specialized equipment may also be needed, adding to the overall expense.

Regional Price Variations in the US

Regional differences within the US can affect installation costs due to variations in labor rates, regulatory requirements, and other local factors.

Long-term Maintenance Costs

Understanding and budgeting for long-term maintenance is crucial for the overall cost-effectiveness of well casing.

Preventative Maintenance Budgeting

Allocating funds for regular maintenance can help prevent costly repairs and extend the lifespan of the well casing.

Insurance and Liability Considerations

Insurance costs and liability considerations should also be factored into the overall cost analysis to ensure comprehensive financial planning.

Conclusion: Ensuring Successful Well Casing Implementation

Understanding what’s a well casing and its definition is crucial for various industries, including water supply and oil and gas extraction. A well casing is a structural component that lines the wellbore, providing stability and preventing contamination.

Proper well casing design, installation, and maintenance are essential for ensuring the integrity and safety of wells. By choosing the right materials and following best practices, operators can minimize risks and optimize well performance.

Effective well casing implementation requires careful consideration of factors such as depth, diameter, and strength requirements. Regular maintenance and repair are also vital to prevent corrosion and other issues that can compromise well integrity.

By following the guidelines and best practices outlined in this article, operators can ensure successful well casing implementation and maintain the long-term viability of their wells.