Trash Pumps 101: Everything You Should Know About These Versatile Machines

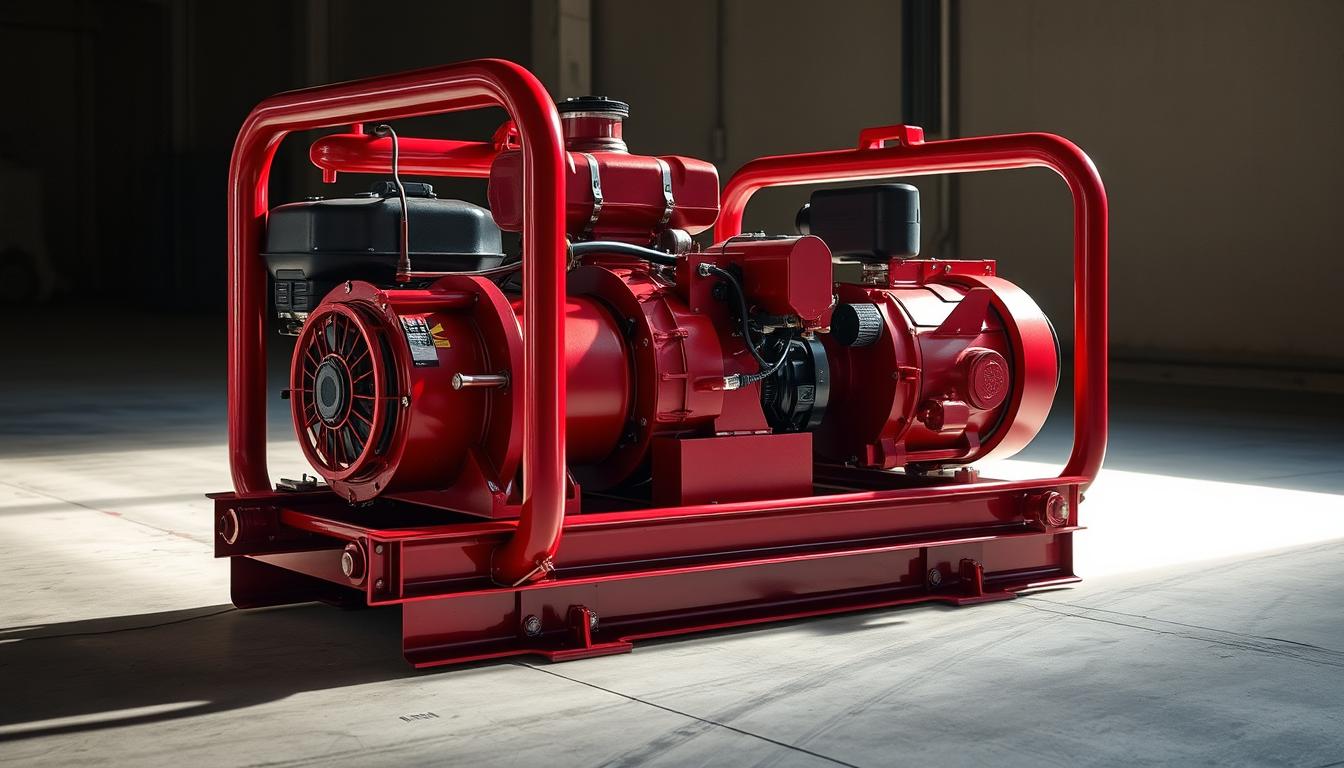

Have you ever wondered how industries manage to handle liquids with solids in challenging environments? The answer lies in the robust functionality of trash pumps, self-contained centrifugal pumps designed to tackle such tasks efficiently.

Trash pumps are equipped with a power source, such as a diesel engine, and a pump end mounted on a frame or trailer, making them versatile for various applications. Their ability to handle liquids with solids makes them indispensable in different industries.

Understanding the trash pump definition is crucial for appreciating their role in facilitating complex operations. As we delve into the world of trash pumps, you’ll discover their importance and the benefits they bring to various sectors.

Key Takeaways

- Trash pumps are self-contained centrifugal pumps.

- They are designed to handle liquids with solids.

- Equipped with a power source and pump end on a frame or trailer.

- Versatile for various industrial applications.

- Indispensable in challenging environments.

What Is a Trash Pump? Definition and Core Functionality

Trash pumps are engineered to tackle the toughest pumping jobs, involving dirty water, solids, and other materials that standard pumps can’t handle. They are designed to be robust and versatile, making them ideal for various applications across different industries.

The definition of a trash pump revolves around its capability to handle debris and solids, unlike standard water pumps that are designed for clean water. This functionality is crucial in environments where the water is contaminated with large amounts of debris.

Key Components and Design Features

Trash pumps are built with specific components that enable them to handle tough materials. The key components include a robust impeller designed to handle large solids, a durable casing that withstands abrasive materials, and a powerful engine or motor that drives the pump.

The design features of trash pumps also include a wide inlet and outlet to facilitate the passage of large debris. Additionally, they are often equipped with self-priming technology, which allows them to start pumping without the need for external priming.

| Component | Feature | Benefit |

|---|---|---|

| Robust Impeller | Handles large solids | Increased durability |

| Durable Casing | Withstands abrasive materials | Longer lifespan |

| Powerful Engine/Motor | Drives the pump efficiently | Enhanced performance |

How Trash Pumps Differ from Standard Water Pumps

The primary difference between trash pumps and standard water pumps lies in their ability to handle debris and solids. While standard water pumps are designed for clean or slightly contaminated water, trash pumps can handle water with large amounts of debris.

Trash pumps are also designed to be more robust, with features such as a larger inlet and outlet, and a more powerful engine or motor. This makes them suitable for challenging environments where standard pumps would fail.

The History and Evolution of Trash Pumps

The evolution of trash pumps is a story of innovation and adaptation to the needs of various industries. These machines have become indispensable in handling challenging environments and materials.

Origins of Industrial Pumping Technology

The history of trash pumps is closely tied to the development of industrial pumping technology. Early pumps were often cumbersome and lacked the capability to handle debris and solid materials effectively. However, as industries evolved, so did the technology behind these pumps. The introduction of more robust materials and designs enabled pumps to handle tougher applications, laying the groundwork for modern trash pumps. The benefits of using a trash pump became apparent as they began to be used in various industrial settings.

Modern Innovations in Trash Pump Design

In recent years, trash pump design has seen significant innovations, driven by the demand for more efficient and capable machines. Modern trash pumps are designed to handle a wide range of materials, from water and mud to large debris. Advances in materials science and engineering have led to pumps that are not only more powerful but also more durable. These advancements have expanded the trash pump applications across different sectors, including construction, mining, and emergency response.

| Feature | Traditional Pumps | Modern Trash Pumps |

|---|---|---|

| Material Handling | Limited to clean water or small debris | Capable of handling large debris and solids |

| Durability | Prone to clogging and wear | More durable with advanced materials |

| Efficiency | Less efficient, often requiring manual priming | More efficient with self-priming technology |

How Trash Pumps Work: The Technical Breakdown

The functionality of trash pumps is rooted in their ability to handle liquids with solids, making them a vital tool in industries ranging from construction to mining. These pumps are designed to efficiently move liquids that contain debris, which is achieved through a combination of centrifugal force and advanced pumping technology.

Internal Mechanisms and Pumping Process

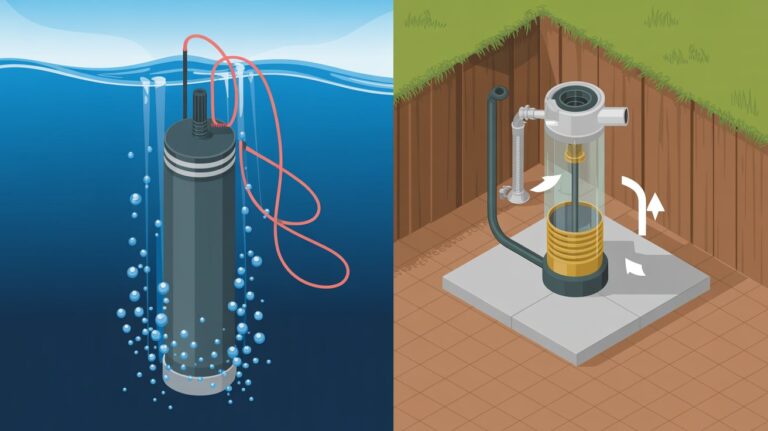

Trash pumps utilize a centrifugal pumping mechanism, where the rotation of an impeller creates a centrifugal force that pushes the liquid and solids through the pump. The impeller design is critical, as it determines the pump’s ability to handle solids of various sizes. The pumping process involves drawing in the liquid and solids through an inlet, which is then accelerated by the impeller, creating the necessary pressure to discharge the mixture.

The internal mechanisms are engineered to withstand the rigors of handling abrasive materials, ensuring durability and reliability. The pump’s casing and impeller are typically made from robust materials that resist wear and tear, extending the pump’s lifespan.

Self-Priming Technology Explained

One of the key features of modern trash pumps is their self-priming capability. This technology allows the pump to automatically remove air from the suction line, creating a vacuum that draws in the liquid. Self-priming technology is essential for maintaining the pump’s efficiency and preventing dry running, which can cause damage.

The self-priming mechanism involves a combination of design features, including a specialized impeller and a priming chamber. When the pump is started, the impeller creates a vacuum that draws liquid into the priming chamber, which then facilitates the pumping process. This technology is particularly useful in applications where the pump may need to operate intermittently or handle liquids with varying levels of solids.

Types of Trash Pumps Available on the Market

Understanding the types of trash pumps available is crucial for selecting the right equipment for your needs. The diverse range of trash pumps caters to various applications, including construction, industrial, and residential uses.

Gas-Powered Trash Pumps

Gas-powered trash pumps are ideal for heavy-duty applications where electricity is not available. They offer high portability and can handle large volumes of water with debris. These pumps are commonly used in construction sites and during emergency flood responses.

Electric Trash Pumps

Electric trash pumps are suitable for applications where a power source is readily available. They are generally quieter and produce less vibration compared to gas-powered models. Electric trash pumps are often used in industrial settings and for dewatering purposes.

Hydraulic Trash Pumps

Hydraulic trash pumps are powered by hydraulic systems, making them perfect for use with excavators, backhoes, and other heavy machinery. They are highly effective for handling large debris and are commonly used in mining and industrial operations.

Diaphragm Trash Pumps

Diaphragm trash pumps use a flexible diaphragm to pump water and debris. They are known for their ability to handle viscous materials and are often used in applications requiring gentle handling of the pumped material, such as in certain industrial processes.

When choosing a trash pump, it’s essential to consider the specific requirements of your application, including the type of debris, the volume of water to be pumped, and the power source available. By understanding the different types of trash pumps available, you can make an informed decision that enhances the efficiency and effectiveness of your operations.

Key Features to Look for When Choosing a Trash Pump

When it comes to choosing a trash pump, several critical factors must be considered to ensure optimal performance. A trash pump is a significant investment, and selecting the right one can make a substantial difference in its effectiveness and longevity.

Flow Rate and Head Height Considerations

The flow rate and head height are crucial parameters that determine the pump’s ability to handle the required volume of water and the height to which it can be pumped. Flow rate is typically measured in gallons per minute (GPM), while head height is measured in feet. Understanding these specifications is vital to ensure that the pump meets the demands of the application.

| Flow Rate (GPM) | Head Height (Feet) | Application |

|---|---|---|

| 0-100 | 0-20 | Residential Dewatering |

| 100-500 | 20-50 | Construction Site Dewatering |

| 500+ | 50+ | Industrial and Mining Operations |

Solids Handling Capability and Impeller Design

The ability of a trash pump to handle solids is a key feature, especially in applications where debris is common. The impeller design plays a significant role in this capability. Pumps with a robust impeller design can handle larger solids, making them more versatile for challenging environments.

Durability and Construction Materials

The durability of a trash pump is largely influenced by its construction materials. Pumps made from high-quality, corrosion-resistant materials such as stainless steel or heavy-duty plastics tend to have a longer lifespan and require less maintenance. Investing in a durable trash pump can reduce long-term costs and enhance reliability.

By carefully evaluating these key features, users can select a trash pump that meets their specific needs, whether for residential, construction, or industrial applications. Understanding the benefits of using a trash pump, such as efficiency and cost-effectiveness, can further guide the selection process.

Benefits of Using a Trash Pump for Challenging Environments

The versatility and durability of trash pumps make them a preferred choice for handling debris and solid materials in demanding conditions. These pumps are designed to operate efficiently in environments where standard pumps would fail, making them invaluable in various industries.

Handling Debris and Solid Materials

One of the primary benefits of trash pumps is their ability to handle debris and solid materials that would clog or damage standard pumps. Industrial trash pumps are particularly adept at handling large solids, making them ideal for applications where debris is common.

- Capable of handling solids up to 3 inches in diameter

- Designed to pump dirty water with high concentrations of debris

- Ideal for construction sites, mining operations, and industrial settings

Time and Labor Savings

Using a trash pump can significantly reduce the time and labor required for dewatering and debris removal. By efficiently pumping out water and debris, these pumps enable workers to focus on other critical tasks, thereby increasing productivity.

For instance, in construction site dewatering, trash pumps can remove large volumes of water quickly, allowing construction to proceed without delay.

Versatility Across Multiple Applications

Trash pumps are not limited to a single application; they are versatile machines that can be used in a variety of settings, from construction and mining to agricultural and emergency response situations. Their ability to handle different types of debris and operate in challenging conditions makes them a valuable asset across multiple industries.

The benefits of using a trash pump are clear: they offer a robust solution for handling debris, saving time and labor, and providing versatility across various applications. Whether you’re dealing with construction site dewatering or industrial operations, a trash pump is an essential tool that can enhance efficiency and productivity.

Common Applications and Uses for Trash Pumps

From construction sites to agricultural fields, trash pumps play a crucial role in managing water and debris. Their versatility and robust design make them essential in a variety of challenging environments.

Construction Site Dewatering

One of the primary uses of trash pumps is in construction site dewatering. These pumps are capable of removing large volumes of water, including water with debris and sediment, making them ideal for keeping construction sites dry and safe. Efficient dewatering is crucial for the progress of construction projects, as it prevents delays and ensures a stable working environment.

Mining and Industrial Operations

Trash pumps are also widely used in mining and industrial operations. They are used to handle abrasive slurries and wastewater, making them indispensable in these sectors. The durability and reliability of trash pumps under harsh conditions are key factors in their adoption in mining and industrial applications.

Agricultural and Irrigation Uses

In agriculture, trash pumps are utilized for irrigation purposes, especially in areas where water sources may contain debris. They help in distributing water efficiently across fields, supporting agricultural productivity. The ability of trash pumps to handle water with solids makes them particularly useful in agricultural settings.

Emergency Flood Response and Disaster Recovery

During emergencies such as floods, trash pumps are critical in response and recovery efforts. They are used to quickly remove floodwater, reducing the impact of the disaster on communities and infrastructure. As noted by emergency response experts, “Trash pumps are invaluable in the aftermath of a flood, enabling rapid dewatering and minimizing damage.”

Trash pumps are a testament to the importance of versatile and robust machinery in various industries. Their applications range from construction and mining to agriculture and emergency response, highlighting their utility and value.

Trash Pumps in Different Settings: Industrial, Construction, and Residential

The adaptability of trash pumps makes them suitable for a wide range of applications, including industrial, construction, and residential uses. Their ability to handle debris and wastewater efficiently makes them a valuable asset across various environments.

Heavy-Duty Industrial Trash Pump Applications

In industrial settings, trash pumps are used for handling heavy wastewater and debris. These pumps are designed to withstand harsh conditions and are often used in manufacturing plants, processing facilities, and other industrial environments where wastewater management is critical. Industrial trash pumps are built with durable materials and are capable of handling large volumes of waste.

Construction Site Requirements and Solutions

On construction sites, trash pumps play a vital role in dewatering and managing wastewater. They help in removing water and debris from excavation sites, ensuring that construction work can proceed without interruption. The construction site requirements for trash pumps include high flow rates and the ability to handle solids, making them an essential tool for site managers.

| Application | Key Requirements | Benefits |

|---|---|---|

| Industrial | High durability, large volume handling | Efficient wastewater management |

| Construction | High flow rate, solids handling | Dewatering and site preparation |

| Residential | Ease of use, compact design | Effective for small-scale wastewater management |

Residential and Small Property Uses

For residential and small property uses, residential trash pumps are designed to be compact and user-friendly. They are ideal for managing wastewater in smaller applications, such as in home renovations or small-scale agricultural projects. These pumps are typically easier to install and maintain than their industrial counterparts.

In conclusion, trash pumps are versatile and can be adapted to various settings, from heavy-duty industrial applications to residential uses. Their ability to handle debris and wastewater makes them an indispensable tool across different environments.

Maintenance, Safety, and Environmental Considerations

To maximize the benefits of using a trash pump, it’s essential to prioritize maintenance and safety. Trash pumps are versatile machines used in various applications, including construction site dewatering, mining, and emergency flood response. Ensuring their proper operation not only enhances their longevity but also contributes to a safer working environment.

Routine Maintenance Schedule

Regular maintenance is key to the efficient operation of trash pumps. This includes checking and replacing worn-out parts, such as impellers and seals, and ensuring that the pump is properly lubricated. A routine maintenance schedule helps in identifying potential issues before they become major problems, thus minimizing downtime and extending the pump’s lifespan.

- Regularly inspect the pump and its components for wear and tear.

- Change oil and lubricants as recommended by the manufacturer.

- Clean the pump and its surroundings to prevent clogging and damage.

Troubleshooting Common Issues

Despite regular maintenance, issues may arise. Common problems include reduced flow rate, unusual noises, and overheating. Troubleshooting these issues promptly is crucial. For instance, a decrease in flow rate could indicate a clogged impeller or a problem with the suction line. Identifying and addressing these issues early can prevent more significant problems.

Safety Protocols and Environmental Best Practices

Safety protocols are paramount when operating trash pumps. Operators should wear appropriate personal protective equipment (PPE), and the pump should be placed on a stable surface. Additionally, environmental considerations, such as preventing oil spills and managing waste properly, are crucial. By adhering to these practices, the risk of accidents and environmental damage can be significantly reduced.

By following these guidelines, users can ensure that their trash pumps operate effectively and safely, contributing to successful project outcomes in various trash pump applications, from construction to emergency response.

Conclusion: The Enduring Value of Trash Pumps in Modern Applications

Trash pumps have proven to be invaluable assets across various industries, from construction and mining to residential and emergency response situations. Understanding what is a trash pump and its definition is crucial in appreciating its role in handling challenging environments.

A trash pump, by definition, is a type of pump designed to handle dirty water and debris, making it an essential tool for dewatering and other applications. The versatility and robustness of trash pumps have made them a staple in modern industries.

The ability of trash pumps to handle solids and debris, coupled with their durability and construction, makes them ideal for a wide range of applications. Whether it’s construction site dewatering, mining operations, or emergency flood response, trash pumps continue to demonstrate their value.

As industries continue to evolve, the demand for reliable and efficient pumping solutions will remain. Trash pumps, with their proven track record and adaptability, are poised to remain a vital component in modern applications.