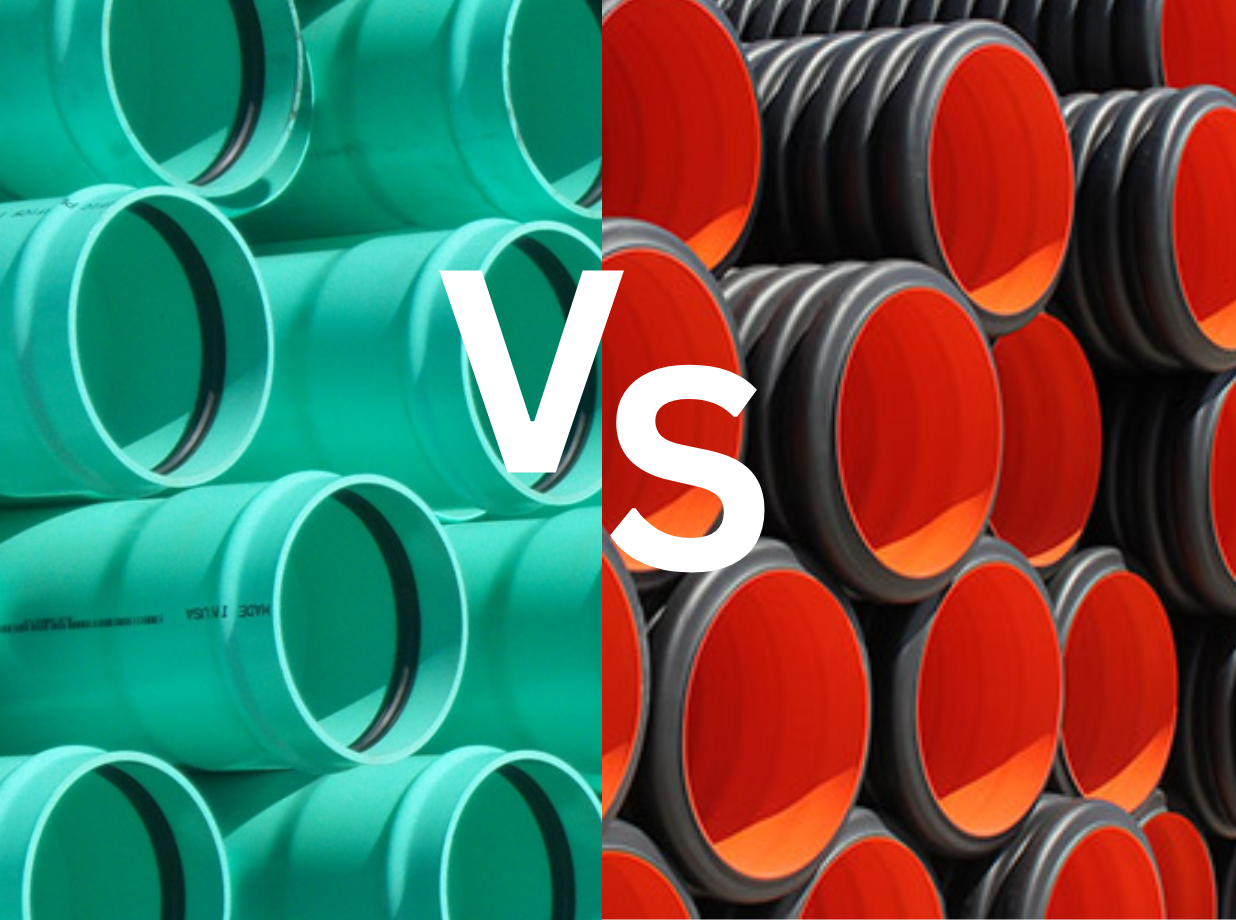

Choosing the Right Pipe: SDR 35 vs Corrugated

Key Takeaways

- SDR 35 pipes are known for their strength and durability, making them a reliable choice for underground drainage systems.

- Corrugated pipes are flexible and lightweight, making them easier to install and maneuver in tight spaces.

- SDR 35 pipes have a smooth interior, reducing the risk of clogs and blockages, while corrugated pipes have a ribbed exterior for added strength.

- When choosing between SDR 35 and corrugated pipes, consider factors such as soil conditions, installation ease, and long-term maintenance needs.

- Ultimately, the decision between SDR 35 and corrugated pipes will depend on the specific requirements of the project, as each type has its own set of pros and cons.

Introduction to Pipe Selection

The selection of the right pipe for a project is a critical decision that can have significant implications for the project’s success, longevity, and overall performance. Two of the most common types of pipes used in various applications are SDR 35 and corrugated pipes. Understanding the characteristics, advantages, and disadvantages of these two pipe options is essential for making an informed choice that aligns with the specific requirements of your project.

In this article, we will delve into the details of SDR 35 and corrugated pipes, exploring their unique features, strengths, and limitations. By the end of this comprehensive guide, you will be equipped with the knowledge to make an informed decision on the most suitable pipe for your project.

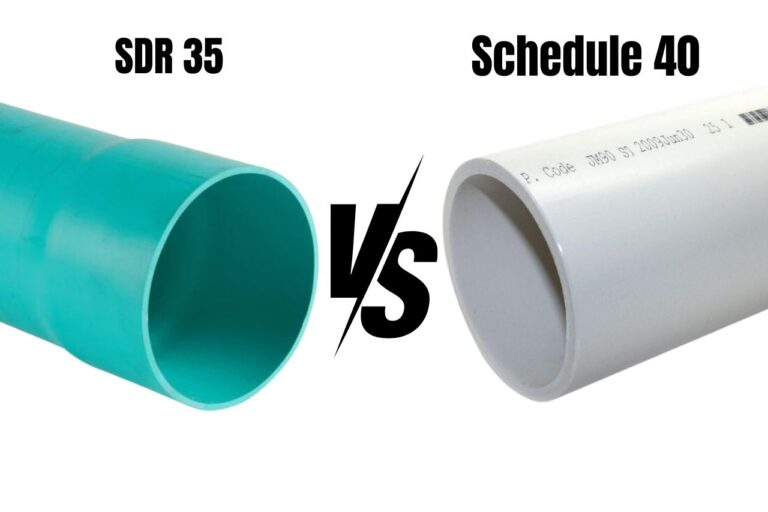

Understanding SDR 35 Pipes

SDR 35 pipes, also known as Standard Dimension Ratio 35 pipes, are a type of plastic pipe commonly used in various applications, including drainage, sewage, and underground utility systems. These pipes are characterized by their specific composition and dimensions, which contribute to their unique properties and performance.

The defining feature of SDR 35 pipes is their standard dimension ratio, which refers to the ratio of the pipe’s outside diameter to its wall thickness. This ratio of 35 ensures that the pipes are designed to withstand the pressures and stresses encountered in their intended applications. SDR 35 pipes are typically made from polyvinyl chloride (PVC) or other durable plastic materials, providing them with a high level of strength and durability.

One of the primary advantages of SDR 35 pipes is their exceptional durability and strength. These pipes are capable of withstanding significant loads and pressures, making them well-suited for applications where structural integrity is of utmost importance. Additionally, SDR 35 pipes are relatively easy to install and maintain, as they can be easily cut, joined, and accessed for any necessary repairs or modifications.

However, SDR 35 pipes do have some limitations. Due to their rigid nature, they may exhibit limited flexibility and adaptability, which can be a drawback in certain applications where the pipe needs to navigate through complex terrain or accommodate changes in the surrounding environment. Furthermore, SDR 35 pipes can be susceptible to cracking or breaking under certain conditions, such as extreme temperature fluctuations or ground movement. In some environments, they may also be prone to corrosion, which can compromise their long-term performance.

Exploring Corrugated Pipes

Corrugated pipes, on the other hand, are a type of pipe characterized by their distinctive wavy or ribbed exterior design. These pipes are commonly used in a variety of applications, including drainage, culverts, and stormwater management systems.

The defining feature of corrugated pipes is their corrugated structure, which provides them with enhanced flexibility and adaptability. This design allows the pipes to bend and conform to the contours of the surrounding terrain, making them well-suited for installations in areas with uneven or challenging ground conditions.

One of the primary advantages of corrugated pipes is their exceptional flexibility and adaptability. The corrugated structure enables these pipes to be easily maneuvered and installed, even in tight spaces or around obstacles. Additionally, corrugated pipes are highly resistant to corrosion and weathering, making them a durable choice for outdoor and underground applications.

Another key advantage of corrugated pipes is their ease of installation and handling. Due to their lightweight and flexible nature, corrugated pipes can be quickly and efficiently installed, often requiring less specialized equipment and labor compared to their rigid counterparts.

However, corrugated pipes do have some limitations. While their flexibility is a significant advantage, it can also lead to potential issues under heavy loads or in applications where structural integrity is of paramount importance. Corrugated pipes may be more susceptible to collapse or deformation under such conditions, which can compromise their performance and longevity.

Additionally, the corrugated design of these pipes can result in a reduced flow capacity compared to smooth-walled pipes, as the corrugations can create turbulence and resistance to fluid flow. This factor should be carefully considered when selecting pipes for applications where high flow rates or efficient drainage are critical.

Factors to Consider When Choosing Between SDR 35 and Corrugated Pipes

When it comes to selecting the right pipe for your project, there are several key factors to consider to ensure you make an informed decision that aligns with your specific requirements.

One of the primary considerations is the intended use and application of the pipe. SDR 35 pipes are generally better suited for applications where structural integrity and load-bearing capacity are essential, such as in underground utility systems or sewage lines. Corrugated pipes, on the other hand, may be more appropriate for drainage, culvert, or stormwater management applications where flexibility and adaptability are more important.

Another crucial factor to consider is the environmental conditions and soil characteristics of the project site. SDR 35 pipes may perform better in stable, well-compacted soil conditions, while corrugated pipes may be more suitable for areas with uneven terrain or softer soil, as they can better conform to the surrounding environment.

Cost and budget considerations are also important when choosing between SDR 35 and corrugated pipes. While SDR 35 pipes may have a higher initial installation cost, they may offer long-term cost savings due to their durability and reduced maintenance requirements. Conversely, corrugated pipes may have a lower upfront cost, but their potential for deformation or collapse under heavy loads may result in higher maintenance or replacement costs over time.

Installation and performance requirements are also crucial factors to consider. SDR 35 pipes may be easier to install and handle in certain situations, while corrugated pipes may be more suitable for applications where flexibility and ease of installation are paramount. Additionally, the flow capacity and drainage efficiency of the pipes should be evaluated to ensure they meet the specific requirements of your project.

Finally, regulatory and compliance factors should not be overlooked. Local building codes, environmental regulations, and industry standards may dictate the specific pipe types and specifications that are acceptable for your project. Ensuring compliance with these requirements is essential to avoid any legal or regulatory issues.

In conclusion, the choice between SDR 35 and corrugated pipes ultimately depends on a careful evaluation of the project’s unique requirements, environmental conditions, cost considerations, and performance needs. By understanding the strengths, weaknesses, and applications of these two pipe types, you can make an informed decision that will contribute to the success and longevity of your project.

Frequently Asked Questions

What is SDR 35 pipe?

SDR 35 pipe is a type of PVC pipe commonly used for underground sewer and drainage applications. The “SDR” stands for “standard dimension ratio,” which is a way of indicating the pipe’s wall thickness in relation to its diameter.

What is corrugated pipe?

Corrugated pipe is a type of pipe with a series of ridges and grooves on its surface, giving it added strength and flexibility. It is commonly used for drainage and stormwater management applications.

What are the pros of SDR 35 pipe?

SDR 35 pipe is known for its smooth interior, which allows for efficient flow of sewage and drainage. It is also durable and resistant to chemicals and corrosion, making it a long-lasting option for underground applications.

What are the cons of SDR 35 pipe?

One potential downside of SDR 35 pipe is its rigidity, which can make it more difficult to install in certain situations. It is also more susceptible to damage from heavy loads or shifting soil.

What are the pros of corrugated pipe?

Corrugated pipe is lightweight and flexible, making it easier to handle and install, especially in areas with uneven terrain. Its corrugated design provides added strength and allows for greater flexibility in the layout of drainage systems.

What are the cons of corrugated pipe?

One potential drawback of corrugated pipe is its rough interior, which can impede the flow of sewage and drainage. It is also more susceptible to damage from chemicals and corrosion compared to SDR 35 pipe.