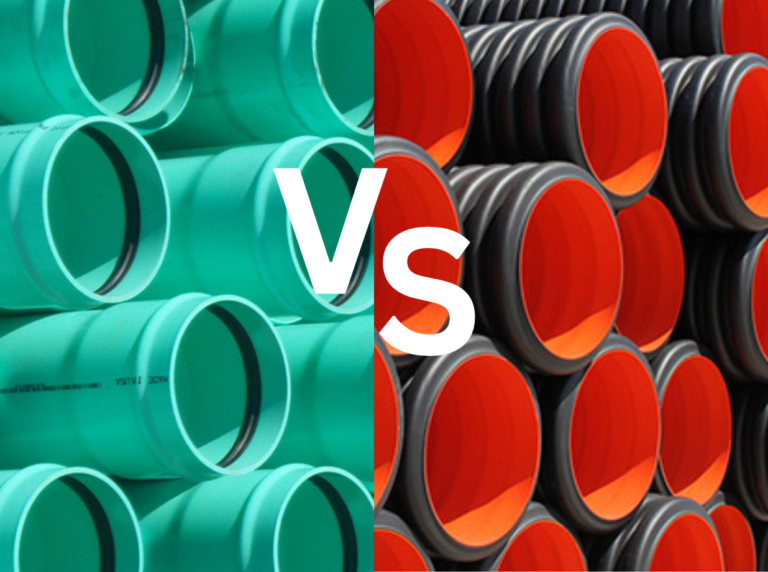

Understanding the Differences: SDR 35 vs Schedule 40 Pipes

Choosing the right pipes for your plumbing or drainage system can be confusing. SDR 35 and Schedule 40 pipes are two common options, each with their own uses. SDR 35 pipes are for underground sewer and drainage systems, while Schedule 40 pipes are for pressurized water systems. This article explores the characteristics, applications, and benefits of each type, helping you make an informed decision. Whether you’re a professional or a DIY enthusiast, this guide provides the knowledge you need for a successful project. Let’s uncover the differences between SDR 35 and Schedule 40 pipes!

Composition and Characteristics of SDR 35 Pipes

SDR 35 pipes, also known as “Standard Dimension Ratio 35 pipes,” are made from a type of PVC (Polyvinyl Chloride) material. This type of pipe is specifically designed for underground sewer and drainage systems. SDR 35 pipes have a smooth interior surface, which allows for efficient flow and prevents clogging. The pipe is lightweight and easy to handle, making it a popular choice among contractors and homeowners alike.

One of the key characteristics of SDR 35 pipes is their high resistance to chemicals and corrosion. This makes them suitable for use in harsh environments, such as areas with high levels of acidity or alkalinity. Additionally, SDR 35 pipes have a high impact strength, which means they can withstand heavy loads and pressure without cracking or breaking. These pipes are also resistant to ultraviolet (UV) radiation, ensuring their longevity even when exposed to sunlight.

Overall, SDR 35 pipes offer a durable and cost-effective solution for underground sewer and drainage systems. Their composition and characteristics make them suitable for a wide range of applications, from residential to commercial projects.

Composition and Characteristics of Schedule 40 Pipes

Schedule 40 pipes, on the other hand, are made from a different type of PVC material. These pipes are primarily used for pressurized water systems, such as potable water supply lines and irrigation systems. Schedule 40 pipes have a thicker wall compared to SDR 35 pipes, which gives them higher pressure-bearing capabilities.

The composition of Schedule 40 pipes includes a combination of PVC resin, stabilizers, and other additives. This mixture creates a strong and rigid pipe that can handle high water pressure without deforming. The smooth interior surface of Schedule 40 pipes ensures efficient water flow, minimizing friction and pressure loss.

In terms of characteristics, Schedule 40 pipes excel in their ability to withstand high temperatures. They can handle hot water without warping or melting, making them suitable for applications that involve heating systems or hot water supply. Schedule 40 pipes are also resistant to chemicals, corrosion, and UV radiation, ensuring their durability in various environments.

The combination of durability, pressure-bearing capabilities, and resistance to high temperatures makes Schedule 40 pipes a reliable choice for pressurized water systems. Whether you’re building a residential or commercial project, these pipes can provide the necessary strength and performance.

Differences in Installation Methods for SDR 35 and Schedule 40 Pipes

While both SDR 35 and Schedule 40 pipes serve specific purposes, there are differences in their installation methods. Understanding these differences is crucial to ensure proper installation and functionality of the plumbing or drainage system.

The installation of SDR 35 pipes typically involves a process called “trenchless installation.” This method is preferred for underground sewer and drainage systems as it minimizes disruption to the surrounding area. Trenchless installation involves using specialized equipment to bore a hole underground and insert the pipe without the need for extensive excavation. This method is efficient, cost-effective, and reduces the chances of damage to existing structures or landscaping.

On the other hand, the installation of Schedule 40 pipes follows a more traditional approach. It involves digging trenches and laying the pipes manually. This method requires careful planning and precise measurements to ensure proper alignment and connection between the pipes. While it may be more labor-intensive and time-consuming compared to trenchless installation, the traditional method provides greater flexibility in terms of pipe routing and customization.

When choosing between SDR 35 and Schedule 40 pipes, it’s important to consider the installation method that best suits your project requirements. If you’re looking for a quicker and less disruptive installation process, SDR 35 pipes may be the ideal choice. However, if you need more flexibility and customization options, Schedule 40 pipes may be the better option.

Advantages and Disadvantages of SDR 35 Pipes

SDR 35 pipes offer several advantages that make them a popular choice for underground sewer and drainage systems. Firstly, their lightweight nature makes them easy to transport and handle, reducing labor and installation costs. Additionally, the smooth interior surface of SDR 35 pipes ensures efficient flow and prevents clogging, reducing the risk of blockages and backups. The high resistance to chemicals, corrosion, and UV radiation ensures their longevity and durability in harsh environments.

However, SDR 35 pipes also have certain disadvantages that need to be considered. Due to their lightweight nature, they may be more susceptible to damage from heavy loads or impacts. This means extra care needs to be taken during installation and maintenance to avoid any potential issues. Furthermore, SDR 35 pipes have lower pressure-bearing capabilities compared to Schedule 40 pipes, making them less suitable for pressurized water systems.

Advantages and Disadvantages of Schedule 40 Pipes

Schedule 40 pipes offer several advantages that make them a preferred choice for pressurized water systems. Their thicker wall and rigid composition provide higher pressure-bearing capabilities, making them suitable for applications that involve high water pressure. Schedule 40 pipes can withstand hot water without warping or melting, making them ideal for heating systems or hot water supply. Additionally, their resistance to chemicals, corrosion, and UV radiation ensures their longevity and durability in various environments.

Despite their advantages, Schedule 40 pipes also have a few disadvantages to consider. Their thicker wall makes them heavier and more difficult to handle during installation, potentially increasing labor and installation costs. The traditional installation method, involving trench digging, may also be more time-consuming and disruptive compared to trenchless installation. It’s important to weigh these factors against the specific requirements of your project before making a decision.

Applications and Recommended Uses for SDR 35 Pipes

SDR 35 pipes are primarily designed for underground sewer and drainage systems. They are commonly used in residential, commercial, and industrial projects for the conveyance of wastewater, stormwater, and other non-pressurized fluids. These pipes are suitable for applications such as sanitary sewers, storm sewers, leachate collection systems, and foundation drainage. The lightweight nature of SDR 35 pipes makes them easy to handle and install, reducing labor and installation costs. Additionally, their high resistance to chemicals, corrosion, and UV radiation ensures their durability in harsh underground environments.

Applications and Recommended Uses for Schedule 40 Pipes

Schedule 40 pipes are primarily used for pressurized water systems, including potable water supply lines, irrigation systems, and heating systems. They are suitable for both residential and commercial projects that require high-pressure water flow and delivery. Schedule 40 pipes can handle hot water without warping or melting, making them ideal for applications that involve heating systems or hot water supply. Their resistance to chemicals, corrosion, and UV radiation ensures their durability in different environments.

Cost Comparison between SDR 35 and Schedule 40 Pipes

When it comes to cost, SDR 35 pipes are generally more affordable compared to Schedule 40 pipes. The lower material and manufacturing costs contribute to their budget-friendly nature. However, it’s important to consider the specific requirements of your project and the long-term benefits of each type of pipe. While SDR 35 pipes may have a lower upfront cost, they may not be suitable for pressurized water systems that require the higher pressure-bearing capabilities of Schedule 40 pipes. Therefore, it’s essential to evaluate the overall cost-effectiveness based on the specific needs of your project.

Choosing the Right Pipe for Your Project

Choosing between SDR 35 and Schedule 40 pipes ultimately depends on the specific requirements of your project. Consider factors such as the intended application, pressure requirements, installation method, durability, and cost-effectiveness. If you’re working on an underground sewer or drainage system, SDR 35 pipes may be the most suitable choice due to their lightweight nature, chemical resistance, and cost-effectiveness. On the other hand, if you’re dealing with a pressurized water system that requires higher pressure-bearing capabilities, Schedule 40 pipes would be the ideal choice.

Consult with a professional plumber or contractor to assess your project needs and determine the most appropriate pipe type. They can provide valuable insights and guidance based on their expertise and experience. Remember, selecting the right pipe is crucial for the long-term functionality and success of your plumbing or drainage system.

Conclusion

Understanding the differences between SDR 35 and Schedule 40 pipes is essential for selecting the right option for your plumbing or drainage system. While SDR 35 pipes are commonly used in underground sewer and drainage systems, Schedule 40 pipes are primarily used for pressurized water systems. Each type has its own composition, characteristics, advantages, and disadvantages that need to be considered.

SDR 35 pipes offer a cost-effective and durable solution for non-pressurized underground systems, providing resistance to chemicals, corrosion, and UV radiation. On the other hand, Schedule 40 pipes offer higher pressure-bearing capabilities and can withstand hot water, making them suitable for pressurized water systems.

By considering factors such as intended application, pressure requirements, installation method, durability, and cost-effectiveness, you can make an informed decision and choose the most suitable pipe type for your project. Consulting with a professional plumber or contractor can further assist in ensuring the success of your plumbing or drainage system.

Remember, selecting the right pipe is crucial for the long-term functionality and success of your project. With the knowledge gained from this comprehensive guide, you can confidently navigate the differences between SDR 35 and Schedule 40 pipes and make the best choice for your specific needs.