Do You Need to Glue SDR 35 Pipe?

If you’re into drainage systems or plumbing, you might wonder: do you glue SDR 35 pipe? This article clears up the confusion about gluing SDR 35 pipe. SDR 35 pipe is a popular choice for drainage and sewer lines. It often comes with fittings that make you question: when and if to use glue?

This guide will tell you if you need to glue SDR 35 pipe. We’ll look at its design, uses, and the good and bad of adhesives. You’ll see how joining methods like bell-and-spigot connections compare to gluing. Plus, we’ll find out when cement is a must. Whether you’re a contractor or a DIYer, this article makes SDR 35 pipe installation easy to understand.

Key Takeaways

- SDR 35 pipe is designed for drainage but doesn’t always require glue.

- Gluing depends on pipe type, fittings, and local building codes.

- Traditional methods like gaskets or mechanical couplings are often used instead of adhesives.

- Weather conditions and material compatibility affect glue effectiveness.

- This guide covers step-by-step instructions and code requirements for safe installation.

Understanding SDR 35 Pipe and Its Applications

SDR 35 pipe is a type of PVC material. It has a Standard Dimension Ratio of 35, meaning its diameter is 35 times its wall thickness. This makes it strong yet flexible, perfect for certain plumbing and drainage needs. The question of do you glue SDR 35 pipe comes up, but understanding its design helps explain bonding methods.

Proper installation techniques, including bonding methods, extend the lifespan of SDR 35 systems by 50% or more.

What Is SDR 35 Pipe?

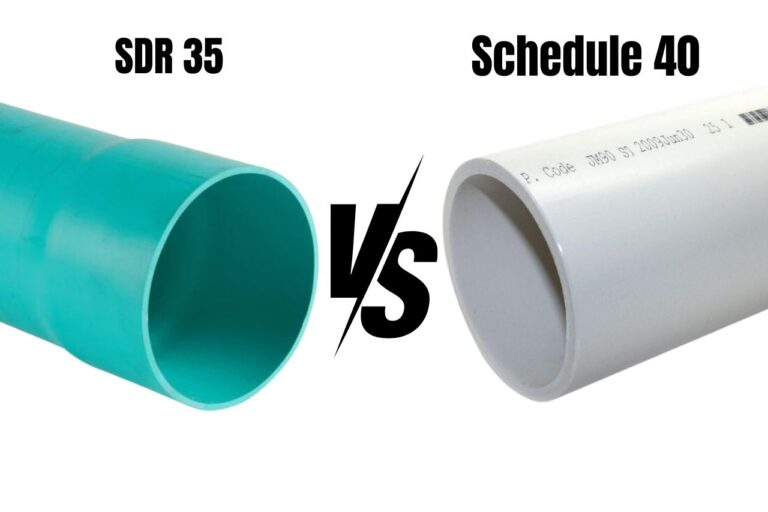

SDR 35 pipe is made for non-pressurized uses. It has thinner walls than rigid materials like Schedule 40 PVC. This makes it lighter and easier to bend in trenches.

Common Uses for SDR 35 Pipe

- Residential and commercial drainage systems

- Septic tank connections and leach fields

- Irrigation networks

- Stormwater management

SDR 35 vs. Other Pipe Types

SDR 35 pipe has a lower pressure rating than DWV pipes but is more flexible. Unlike Schedule 40 PVC, which uses threaded fittings, sdr 35 pipe bonding methods often use solvent welding or gaskets. This shows it’s designed for gravity-fed systems, not high-pressure water lines.

Do You Glue SDR 35 Pipe? The Short Answer

Most SDR 35 pipe installations don’t need gluing. They use gasketed bell-and-spigot joints. But, gluing SDR 35 pipe might be required in certain cases.

| When to Glue | When Not to Glue |

|---|---|

| Local codes demand it | Standard underground drainage |

| Connecting to fixtures like toilets | Bell-and-spigot joints are sufficient |

| Sealing joints in above-ground applications | Most municipal plumbing projects |

Check with local inspectors about do you glue SDR 35 pipe rules. Always look at project guidelines before deciding. For instance, residential fixtures might need adhesive, while commercial drains often don’t.

“Always prioritize code compliance over personal preference,” advises the Plumbing-Union.org guide. “Gluing is situational for SDR 35.”

Quick tip: Use gluing SDR 35 pipe only when joints face pressure or movement. Most plumbers choose factory-fitted joints unless told otherwise.

Traditional Joining Methods for SDR 35 Pipe

Choosing the right connection method is key for a lasting SDR 35 pipe system. Many projects use trusted methods like bell and spigot systems or gasketed joints. These traditional approaches often beat glued joints in most cases. Here’s what to know before deciding between bonding or adhesives.

Bell and Spigot Connections

Bell and spigot joints have a flared bell end and a straight spigot end. The spigot fits into the bell, creating a tight seal without glue. This method is fast to assemble and works well with rubber gaskets for extra security. It doesn’t need primer or curing time, making it perfect for plumbing and drainage systems.

Gasketed Joints

Rubber gaskets between the bell and spigot make a watertight seal. This method is popular for its durability and easy disassembly. Gaskets resist corrosion and pressure changes, making them better for long-term use than glue in many cases.

When Gluing Is Required vs. Optional

Glue is needed in specific situations:

- Repairs: To fix cracked sections or connect non-compatible fittings.

- Special Fittings: Adhesives bond certain elbows or tees not designed for slip joints.

- Code Requirements: Some regions mandate glued joints in high-pressure zones.

For standard installations, traditional methods are the best choice. Always check manufacturer guidelines to avoid overusing sdr 35 pipe glue instructions when unnecessary.

Benefits of Gluing SDR 35 Pipe

Choosing gluing sdr 35 pipe has many benefits for plumbing and construction. Adhesives create a strong bond, making joints seamless. This makes the system better at stopping leaks, especially in high-pressure areas or where the ground shifts a lot.

- Leak Prevention: Glued joints form a permanent seal, reducing risks in critical applications like water supply lines.

- Strength Enhancement: The chemical weld increases overall durability, making the pipe behave as a single unit.

- Cost Efficiency: Fewer repairs over time lower long-term expenses compared to frequently replacing gasketed joints.

- Weather Resilience: Bonds withstand temperature fluctuations better than mechanical connections.

“Proper tips for gluing sdr 35 pipe ensure joints last decades when done correctly,” says plumbing expert Sarah Torres. “Clean surfaces and precise cement application are key to maximizing longevity.”

Glued connections are great for tight spaces where mechanical fittings are too big. For tips for gluing sdr 35 pipe, always follow the manufacturer’s guidelines on primer and cement ratios. This method is perfect for static installations where there’s little movement, ensuring reliability for decades. Whether it’s for irrigation systems or drainage networks, gluing adds a layer of dependability that traditional methods can’t match.

Step-by-Step Guide: How to Glue SDR 35 Pipe

Learning how to glue sdr 35 pipe begins with the right tools and prep. This guide will help you achieve strong, leak-free joints every time.

Materials and Tools You’ll Need

- PVC primer and cement (check labels for SDR 35 compatibility)

- Clean rags or paper towels

- Cutting saw or pipe cutter

- Rubber gloves and safety glasses

- Measuring tape and marker

Preparation Steps

Clean the surfaces well. Use a wire brush to scrape the pipe ends, then wipe with a dry cloth. Measure and cut the pipe to the right length with a miter saw. Test the fit before applying chemicals to avoid mistakes.

Applying Primer and Cement

“Work quickly but carefully—primer dries fast!”

- Apply primer evenly to the pipe end and socket, overlapping both surfaces.

- Wait 10-15 seconds for primer to dry before adding cement.

- Spread cement in a circular motion on both surfaces, then push pieces together firmly.

Proper Curing Times

| Temperature | Curing Time | Notes |

|---|---|---|

| 70°F+ (21°C) | 10-15 minutes | Full strength in 24 hours |

| Cold (below 40°F/4°C) | Double time | Use heat lamps if possible |

Always follow sdr 35 pipe glue instructions on product labels for temperature-specific guidelines.

Best Adhesives and Glues for SDR 35 Pipe

Choosing the best glue for SDR 35 pipe depends on the job and the environment. Match the adhesive’s strength to the pipe’s size and pressure. Here’s what you need to know:

- Regular PVC Cement: Works for pipes under 2 inches. Look for brands like Junction® or Oatey® for standard installations.

- Medium/Heavy-Duty Cements: Use for larger diameters (2”+) or high-pressure systems. Products like Plumb® Professional Strength fill gaps better in thick-walled pipes.

Primers are essential. Purple primer (e.g., SharkBite Purple Primer) is code-approved because it stains the pipe surface, proving full coverage. Avoid clear primers for SDR 35—always opt for purple.

“Without primer, glue won’t bond. Purple shows where you’ve applied it—no guessing if you missed a spot.”

Weather matters. Tip: In cold temps, use Henry® Cold Weather PVC Cement. In heat, avoid direct sun exposure to prevent premature curing. Follow these tips for gluing SDR 35 pipe in extreme conditions:

- Store glue at room temp before use.

- Check manufacturer’s cure time guidelines.

- Use heat guns sparingly—overheating weakens PVC.

Always pair primer and cement from the same brand. Mixing brands may cause failure. Start smart: pick the right formula, prep surfaces, and account for weather. Your joints will last longer with this know-how.

Common Mistakes When Gluing SDR 35 Pipe

Missteps in the sdr 35 pipe glue technique can turn a simple job into a headache. Here’s what to avoid:

- Ignoring surface prep: Dust or oil on pipe ends blocks adhesive bonding. Clean surfaces thoroughly before starting.

- Wrong cement: Use PVC primer first, then compatible solvent weld cement. Generic adhesives weaken joints.

- Rushing alignment: Forcing fittings causes misalignment. Rotate slowly until they click into place.

- Skipping cure time: Disturbing joints before full curing leads to cracks. Wait the full recommended time.

- Overapplying cement: Excess glue pools and weakens seals. Apply a thin, even layer.

| Mistake | Solution |

|---|---|

| Dirty surfaces | Wipe with 90% isopropyl alcohol |

| Uncleaned primer residue | Wait 10-15 seconds after priming before applying cement |

| Improper storage | Store open cement upright to prevent clogging |

Follow these tips for gluing sdr 35 pipe to ensure long-lasting joints. Double-check alignment, let materials cure fully, and always prime before applying cement. A little patience at each step prevents costly leaks later.

Alternative Connection Methods to Consider

While how to glue sdr 35 pipe is a common question, other sdr 35 pipe bonding methods exist for different project needs. Let’s explore options that don’t require adhesive:

Mechanical Couplings

These connectors use clamps or threaded fittings to fasten pipe sections. Brands like Fernco offer PVC-friendly systems that snap into place, creating tight seals without cement. They’re ideal for quick repairs or outdoor installations where curing times are impractical.

Rubber Sleeve Couplings

Rubber sleeves, such as Camloc Flex-Tite couplings, wrap around pipe ends to join materials like metal or polyethylene. Their flexibility makes them perfect for uneven surfaces or temporary setups. They’re also top picks for joining pipe to fittings during emergency repairs.

When to Choose Alternatives Over Gluing

- Wet Conditions: Moisture delays cement curing—opt for couplings in damp environments.

- Future Adjustments: Mechanical joints allow easy disassembly for maintenance or relocation.

- Material Mixes: Rubber sleeves bridge dissimilar materials like steel and PVC without adhesives.

- Time Constraints: Gluing demands patience; mechanical methods speed up assembly for tight deadlines.

Choosing the right method depends on your project’s demands. Whether you’re working with sdr 35 pipe bonding methods for a backyard drain or a commercial build, these alternatives offer flexibility and durability without sacrificing performance.

Building Code Requirements for SDR 35 Pipe Installation

Building codes differ by location but all have rules for installing drainage pipes. Some places need the sdr 35 pipe glue technique in high-pressure spots. Not following these rules can cause fines or delays in your project.

- Slope requirements: At least 1/8 inch per foot for proper flow.

- Support spacing: Every 4–6 feet to prevent sagging.

- Burial depth: 18–36 inches depending on use.

- Inspection access: Cleanouts or access points every 50–100 feet.

| Requirement | Common Standard | Why It Matters |

|---|---|---|

| Slope | 1/8″ per foot | Ensures drainage efficiency and prevents backups. |

| Support Spacing | Every 4–6 ft | Maintains structural integrity over time. |

| Burial Depth | 18–36″ (varies by use) | Protects pipes from freezing or ground shifts. |

| Inspection Access | Every 50–100 ft | Facilitates maintenance and code compliance checks. |

Check with local authorities to confirm the rules. Some areas require the sdr 35 pipe glue instructions for certain uses. Always get the necessary permits and schedule inspections. Not following the rules can lead to expensive rework. Make sure to follow the codes for a successful project.

Conclusion: Making the Right Choice for Your SDR 35 Pipe Project

Deciding if you should glue SDR 35 pipe depends on your project’s needs. It’s important to know about local codes, how you plan to use it, and how long it needs to last. The answer to “do you glue sdr 35 pipe” varies. You need to think about the pressure it will face and the weather it will be in.

When you do choose to glue, pick the best glue for SDR 35 pipe and use primers. Make sure to apply it right to get strong joints. Always follow the curing times and weather guidelines. You might also consider other options like gasketed joints or mechanical couplings. Always check if they meet local codes.

Choosing the right method is key, but the quality of the installation is even more important. Follow all steps from start to finish to avoid leaks or weak spots. Always check the manufacturer’s guidelines and local codes for the best results. Making smart choices from the start will help your project succeed.

Now you’re ready to make the best choice for your project. Focus on doing the installation right. Remember, the right materials and techniques will make your system work as it should. Good luck with your project!

FAQ

Do you glue SDR 35 pipe?

Gluing SDR 35 pipe is not the usual method. It often uses gasketed connections. But, there are times when gluing is needed or helpful.

What is the best glue for SDR 35 pipe?

The top adhesive for SDR 35 pipe is high-quality PVC cement. It should meet ASTM D2564 standards for the best bond.

How do I glue SDR 35 pipe properly?

To glue it right, clean the surfaces first. Then, apply primer and PVC cement evenly. Hold the pieces together for a few seconds for a strong bond.

What are the tips for gluing SDR 35 pipe?

Make sure surfaces are clean and dry. Use the right primer and cement. Let it cure for the right amount of time. Also, align the pipe properly before the adhesive sets.

When is gluing SDR 35 pipe required instead of using gasket methods?

You might need to glue it for specific fittings or repairs. This is especially true if local building codes require it for certain applications.

What preparation steps should I take before gluing?

Before gluing, measure and cut the pipe accurately. Clean the ends to remove dirt or debris. Check the fit before applying adhesive.

Can weather affect the performance of SDR 35 pipe glue?

Yes, weather can affect glue performance. Extreme temperatures and humidity may require special products for proper curing.

What common mistakes should I avoid when gluing SDR 35 pipe?

Don’t use too much or too little cement. Make sure to let it cure properly. Also, prepare surfaces well to avoid leaks or joint failure.

What alternative connection methods are available for SDR 35 pipe?

You can use mechanical couplings or rubber sleeve couplings. These methods provide secure connections without adhesive. They also make disassembly easier in the future.

Are there any building code requirements when installing SDR 35 pipe?

Yes, building codes have specific guidelines. These include connection methods, pipe slope, and burial depth. Always check local codes for compliance.