Understanding the Importance of Backflow Preventers

Have you ever considered what prevents our drinking water from becoming contaminated by pollutants and harmful substances? In our daily lives, many systems work tirelessly behind the scenes to ensure that what you drink is safe. One of the unsung heroes of this vital task is the backflow preventer, a crucial piece of plumbing that often goes unnoticed yet plays a significant role in safeguarding public health.

Understanding Backflow Preventers

Backflow preventers are devices designed to stop water from flowing backward in plumbing systems. This backward flow can occur when there’s a change in pressure, potentially allowing contaminated water to flow into the clean water supply. Understanding backflow preventers is essential for anyone concerned about maintaining a safe water supply in their home or community.

The Basics of Backflow

The term “backflow” refers to the undesirable reversal of water flow in a plumbing system. It can happen due to two primary conditions: backpressure and backsiphonage. Backpressure occurs when the pressure in a system exceeds the pressure of the water supply, while backsiphonage happens when there’s a significant drop in supply pressure, creating a vacuum that pulls water back into the supply. Both scenarios can result in contamination of the public water system.

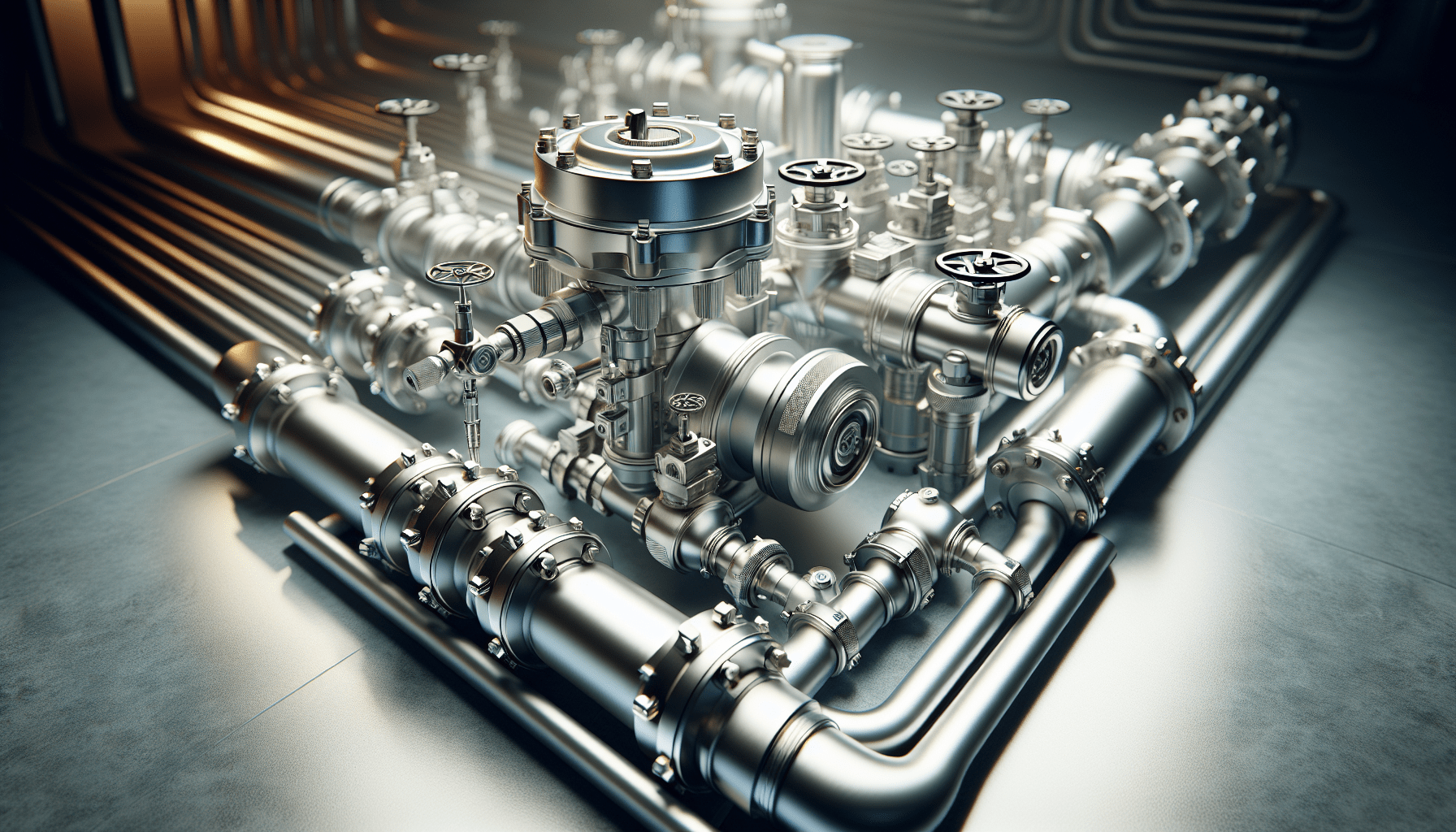

What is a Backflow Preventer?

A backflow preventer is a device installed in plumbing systems to prevent water from flowing back into the public water supply. By blocking the reverse flow of water, these devices protect our drinking water from contamination due to backflow incidents. They are crucial in ensuring that water remains potable and safe for consumption, especially in critical facilities like hospitals, where contamination can have severe consequences.

Types of Backflow Preventers

There are several types of backflow preventers, each designed to address specific backflow scenarios. Understanding the differences between these devices can help you select the appropriate one for any given application. Here’s a quick guide to the most common types of backflow preventers:

1. Atmospheric Vacuum Breaker (AVB)

The AVB is one of the simplest types of backflow preventers. It involves a check valve that relies on gravity and atmospheric pressure to stop backflow. Suitable for low hazard situations, it’s often used in outdoor hose bibs or low-risk sprinkler systems. It’s worth noting that AVBs cannot be installed in any application where continuous pressure is applied, as they’re not designed to withstand it.

2. Pressure Vacuum Breaker (PVB)

A PVB is similar to an AVB but can handle more pressure. This device uses a spring-loaded check valve along with an air inlet. Upon detection of backflow pressure, it opens to the atmosphere, preventing backflow. PVBs are typically used in irrigation systems and other applications that must withstand higher pressure.

3. Double Check Valve Assembly (DCVA)

The DCVA features two consecutive valves that create redundant safety measures against backflow. With advantages such as compact size and versatility, these preventers are widely used in apartment complexes and other medium-to-low risk situations. The double check design ensures that even if one valve fails, the other continues to protect the water supply.

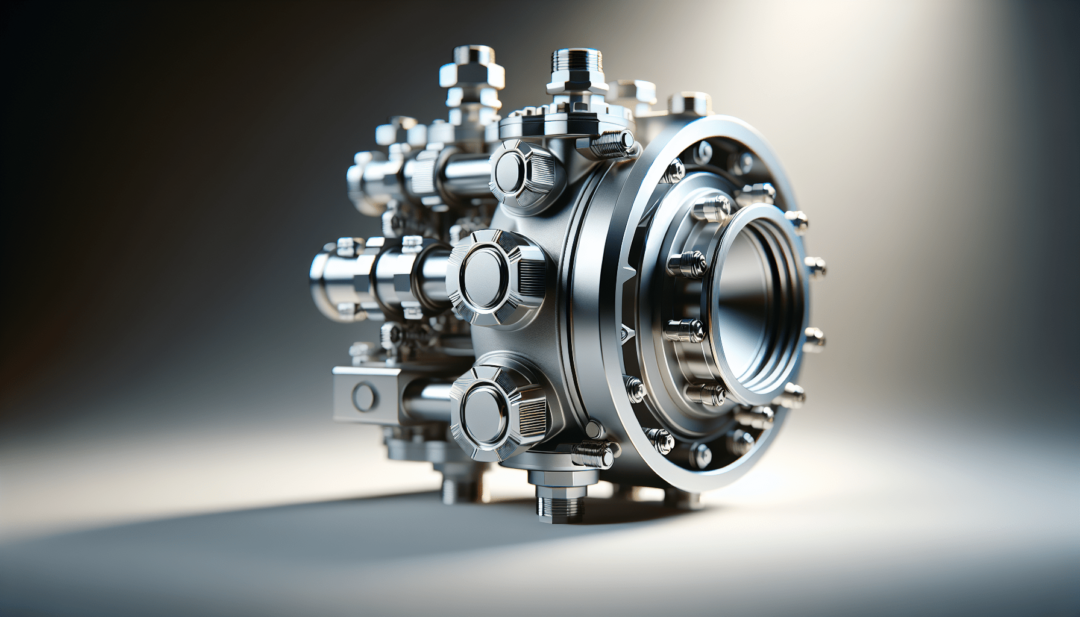

4. Reduced Pressure Zone Device (RPZ)

The RPZ offers maximum protection and is designed for high hazard situations. It includes a pressure-sensing mechanism and a relief valve. If backflow pressure occurs, the relief valve will open to discharge water, preventing any possibility of contamination. RPZ units are commonly utilized in industrial settings where the risk of hazardous contamination is higher.

The table below summarizes the types and their applications:

| Type | Application |

|---|---|

| Atmospheric Vacuum Breaker (AVB) | Low-risk, outdoor hoses, and sprinkler systems |

| Pressure Vacuum Breaker (PVB) | Higher pressure irrigation systems |

| Double Check Valve Assembly (DCVA) | Medium-to-low risk, apartment buildings |

| Reduced Pressure Zone Device (RPZ) | High-risk industrial or chemical facilities |

Why Backflow Preventers are Essential

The significance of backflow preventers extends beyond merely keeping the water clean. Understanding their broader impact helps appreciate why they are integral to our daily lives and infrastructure.

Public Health Protection

Preventing contaminants from entering the public water supply is paramount. Backflow events can introduce microorganisms, chemicals, heavy metals, and even untreated wastewater into the drinking supply, posing serious health risks. By stopping these potential hazards at the source, backflow preventers are crucial in preventing disease outbreaks and ensuring community health.

Legal and Regulatory Compliance

Many countries and regions mandate the use of backflow preventers in specific scenarios, particularly in commercial and industrial settings. Compliance with these regulations isn’t just about avoiding fines—it’s about demonstrating a commitment to safety and well-being. Failure to comply can result in legal action, damage to reputation, and even the temporary closure of businesses.

Ensuring System Integrity

Backflow incidents can damage a water system’s infrastructure. The introduction of contaminants can lead to corrosion, which can significantly reduce the lifespan of pipes and other components. By preventing backflow, these devices also protect the integrity of plumbing systems, thereby reducing maintenance costs and downtime.

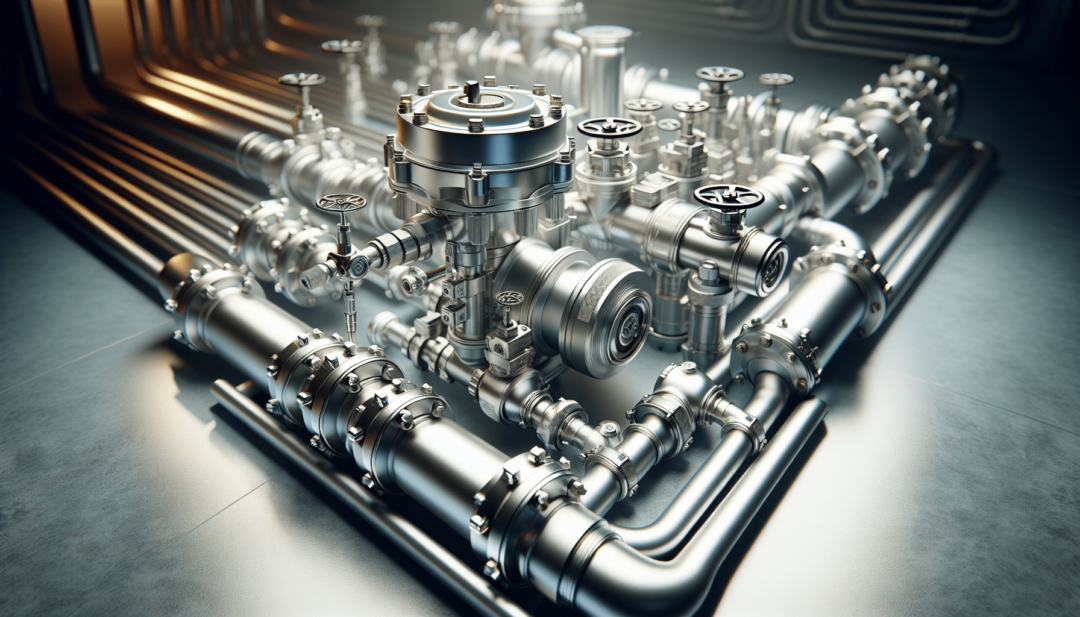

Installation and Maintenance of Backflow Preventers

Much like any other piece of equipment, ensuring that backflow preventers function correctly requires proper installation and regular maintenance. Here are some tips and insights to help you manage these devices effectively.

Correct Installation Practices

Installation of a backflow preventer should always be performed by a qualified professional who understands the nuances of the particular system and device. The location is critical—it must be accessible for testing and maintenance while meeting all local codes and standards. Incorrect installation can negate the benefits of even the most sophisticated backflow preventer.

Regular Testing and Maintenance

Most jurisdictions require regular backflow testing and maintenance to ensure devices are functioning correctly. Annual inspections by certified testers help identify potential failures and maintain compliance with health and safety standards. Regular maintenance not only ensures optimal performance but also extends the lifespan of the backflow preventer.

Signs of Malfunction

Even with regular maintenance, backflow preventers can occasionally malfunction. Signs that your device might need attention include visible water leaks, unusual noises, or changes in water pressure. It’s crucial to address these issues promptly to prevent contamination or system damage.

The Role of Backflow Preventers in Urban Infrastructure

Backflow preventers are integral components of urban infrastructure, ensuring the safe delivery of potable water in various municipal systems. In large cities, the complexity and scale of plumbing networks make backflow prevention even more critical.

Protecting Water Supplies in Cities

In densely populated areas, a single backflow incident can have widespread consequences. Cities often have complex interconnections between commercial, industrial, and residential plumbing systems. Ensuring each link in this chain is adequately protected means implementing backflow prevention measures extensively.

Industrial Applications

Many industries use or produce nonpotable water in their processes, making backflow prevention crucial to avoiding contamination. Facilities like power plants, manufacturing units, and chemical treatment plants rely heavily on robust backflow preventer systems to shield both their operations and the local water supply.

Residential Communities

In residential settings, backflow preventers are installed to safeguard the community’s water supply. This ensures that any plumbing mishaps within individual homes do not affect the broader public supply. For example, swimming pools, irrigation systems, and secondary water sources such as wells may all require some form of backflow prevention.

Potential Challenges and Solutions

Despite their benefits, backflow preventers are not without their challenges. Understanding these issues and knowing how to address them ensures a reliable and effective backflow prevention program.

Common Issues

Some common issues with backflow preventers include improper installation, lack of maintenance, and unwanted pressure fluctuations. Over time, components within the device can wear out, leading to failures if not promptly addressed.

Overcoming Challenges

To overcome these challenges, routine inspections and proactive maintenance schedules are recommended. Training for maintenance personnel and engaging certified professionals for testing can help mitigate the risks. Additionally, raising awareness about the importance of backflow prevention within communities can lead to better compliance and fewer incidents.

Adapting to Technological Advances

Innovation in plumbing technology continues to advance backflow prevention solutions. New devices boast features like remote monitoring and automated testing, which can be pivotal in managing large-scale water networks. Keeping abreast of such advancements can be a crucial step in enhancing backflow prevention systems.

Conclusion

Appreciating backflow preventers involves understanding their crucial role in protecting public health, ensuring compliance with legal standards, and maintaining the integrity of water systems. These devices are not just accessories; they are fundamental components of a safe and reliable water delivery system. By investing in proper installation, rigorous maintenance, and staying informed about modern advancements, you help secure the most indispensable resource—clean water. Remember, although backflow preventers might not be glamorous, their importance to everyday life is monumental. Protecting water quality now ensures a healthier future for everyone.